24

14) Operation of needle bar (left, right) stop (KM-797 Series)

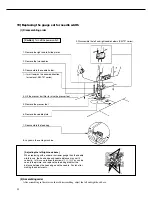

15) Adjusting oil flow in the hook and the

face plate

(1) Hook oil level check

Check whether the amount of oil sprinkled from the

hook for 10 seconds is as is on Figure 42. To adjust the

amount of oil supply, turn the oil supply screw

①

on the

hook base to the right to decrease the oil supply, and to

the left to increase the oil supply. (See Figure 42.)

(2) Face plate oil level check

If there is excessive or insufficient amount of oil

provided to the face plate from the thread take up lever

hinge pin, loosen the face plate oil level adjustment

screw fixing nut

②

and adjust the face plate oil level

adjustment screw

①

. After adjustment, tighten the

fixing nut

②

. (See Figure 43.)

1. When stopping the left needle bar

Place the needle bar trimming direction lever

①

to the L (left) position.

2. When stopping the right needle bar

Place the needle bar trimming direction lever

①

to the R (right) position.

3. When switching to two needle sewing

Vertically press the needle bar return pressing plate

②

. The needle

bar trimming direction lever

①

will return automatically.

※

The needle bar trimming direction lever

①

can be used even

during operation. However, don

’

t use this function when the

needle bar is in the highest position. It works safely from the

point when the needle bar is about 3 mm below the highest point.

Stop

Stop

Non oxidized oil

White paper

[Figure 41]

[Figure 42]

[Figure 43]

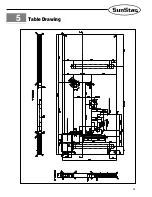

Summary of Contents for KM-757

Page 35: ...35 5 Table Drawing ...