25

※

The present cam stop position: still inside the

complementary straight line of cam leading, right

before the roller drops out upon finishing trimming.

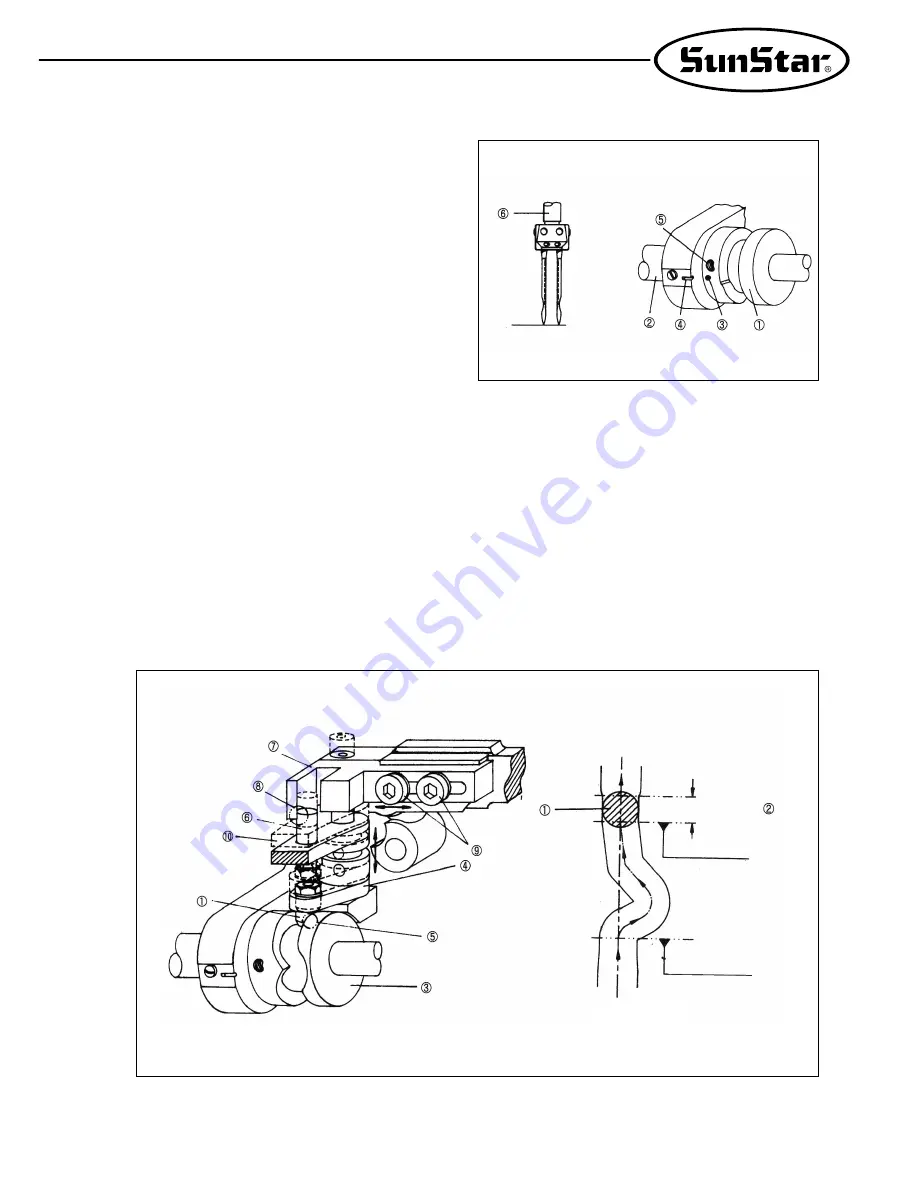

16) Adjusting the trimming device

(1) Adjusting the trimmer driving part

A. Fixing the position of trimming cam

(See Figure 44.)

a) Turn the pulley with hand to place the needle

bar

⑥

at its lowest position.

b) With the left side of the trimming cam

①

softly

attached to the right side of the lower shaft

medium bushing

②

, turn the cam to align the

base point

③

with the carve

④

in the lower shaft

medium bushing crank.

c) Fasten tightly the trimming cam fixing screws (3)

⑤

. Now, turn the pulley with hand to see whether or not the machine turns smoothly.

B. Adjusting the stopper pin holder (See Figure 45.)

a) Once the necessary trimming for trimming cam lead is finished, make sure to turn the machine pulley to place the

trimming cam

③

in the right position, so that the roller

①

can enter the complementary straight line range

②

.

b) Press down the trimmer shake linkage

④

to make the roller

①

come inside the trimming cam

③

,

Adjust the holder

⑦

to make the right equal point of the roller

①

adhere smoothly to the right inside of the

cam

’

s complementary straight line

②

, and the left equal point of the stopper pin

⑥

adhere

⑧

smoothly to the

left inside of the stopper pin holder

⑦

. Once this is done, tightly fasten the fixing screw

⑨

.

Once such adjustments are made, the trimmer shake linkage

④

will not move even when shaken to its sides

(the roller is inside the cam). Make sure to check if the shake linkage

④

returns to its original position

⑩

quickly and smoothly when released. If not, proceed with horizontal adjustment of stopper pin holder

⑦

.

Lowest

point

complementary

straight line

trimming finishing point

movable knife operation

starting point

Trimming cam lead

[Figure 44]

[Figure 45]

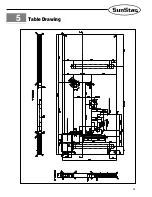

Summary of Contents for KM-757

Page 35: ...35 5 Table Drawing ...