10

2

Installation

Warning

▶

Installation of the machine should be performed by a trained engineer.

▶

Any electrical wiring must be performed by a qualified technician or agent.

▶

The machine weighs over 45kg. At least 2 persons should carry out the installing work.

▶

Plug in after the installation is complete. If the operator mistakenly steps down on the pedal

with the pug in, the machine will start automatically and can cause physical injuries.

▶

Connect the ground (earth) wire. An unstable connection may result in an electric shock or a

malfunction.

▶

Place the belt cover on top of the machine.

▶

Use both hands when bending the machine backwards or returning it to the normal position.

Using only one hand can lead to severe hand injuries due to the weight of the machine.

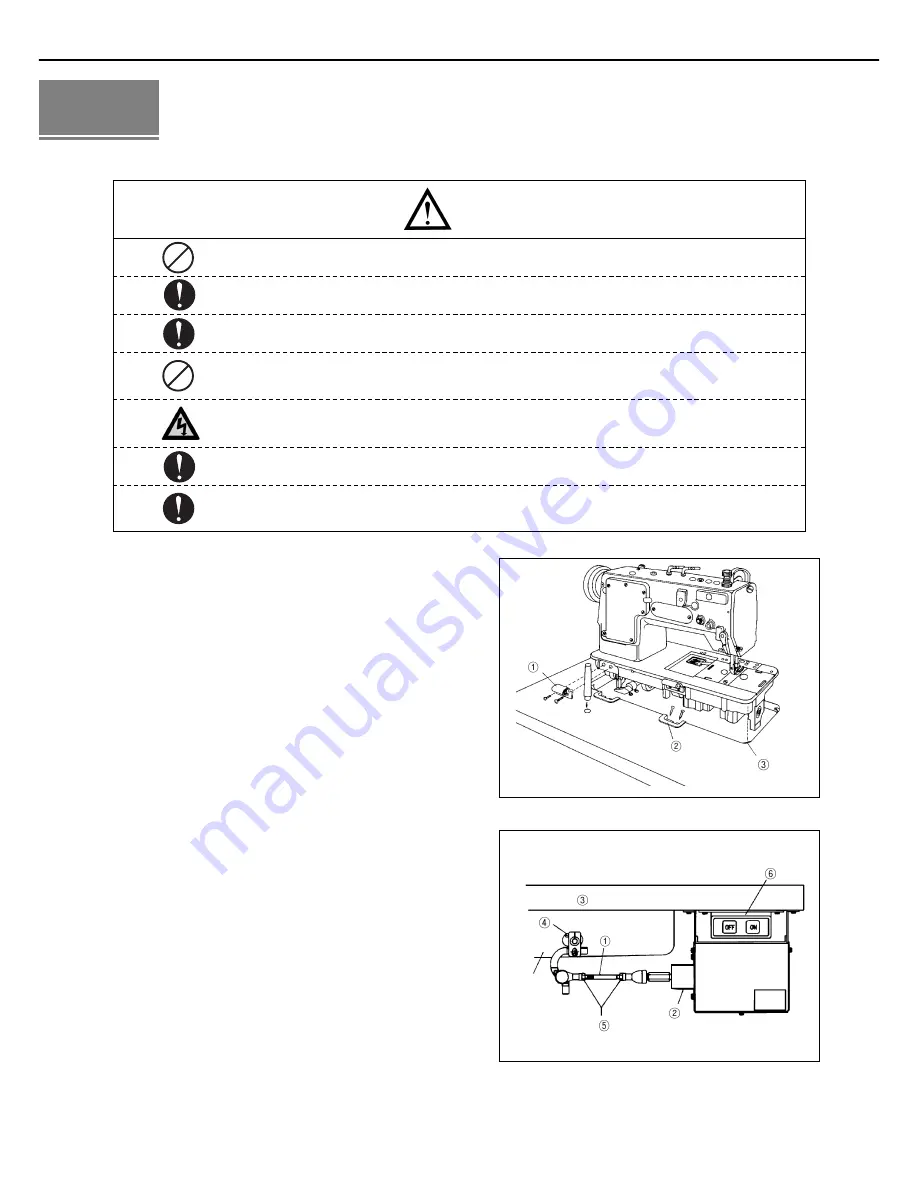

[Figure 1]

Table

Oil Fan

1) Installation of the machine head

Fix the two head hinges

①

to the bed. Insert the hinge rubber

②

and cushion rubber

③

onto the table. Settle the machine on

the table. (see figure 1)

[Figure 2]

A. When attaching the power switch box

⑥

, refer to figure 2 to

make sure that it is placed at the very center of the solenoid

bracket.

B. After attaching the solenoid onto the table, unfasten the

screw

④

to adjust the center of middle linking bar

①

and

the center of solenoid shaft

②

in parallel position with the

lower side of the table

③

. After the adjustment is over,

fasten the screw tightly.

(see figure 2): assembling position diagram can be found

inside the solenoid box.

C. The presser foot height of the sewing machine can be

adjusted after unfastening the fixing nut

⑤

and then turning

the middle linking bar

①

clockwise to raise and

counterclockwise to lower. After finishing the adjustment,

tightly fasten the fixing nut

⑤

.

D. According to the installation position of knee-lifting

solenoid, the operation noise, operation load and presser

foot elevation range may differ. Please assemble so that the

machine will operate smoothly.

2) Installation of knee lifting solenoid and

power switch box