21

[Figure 31]

(750 series)

(790 series)

When using DPx5 needle, it is where

the needle center crosses the hook

edge of the needle bar

’

s lowest point.

When using DPx17 needle, it is where

the needle center crosses the hook

edge of the needle bar

’

s lowest point.

[Figure 30]

[Figure 32]

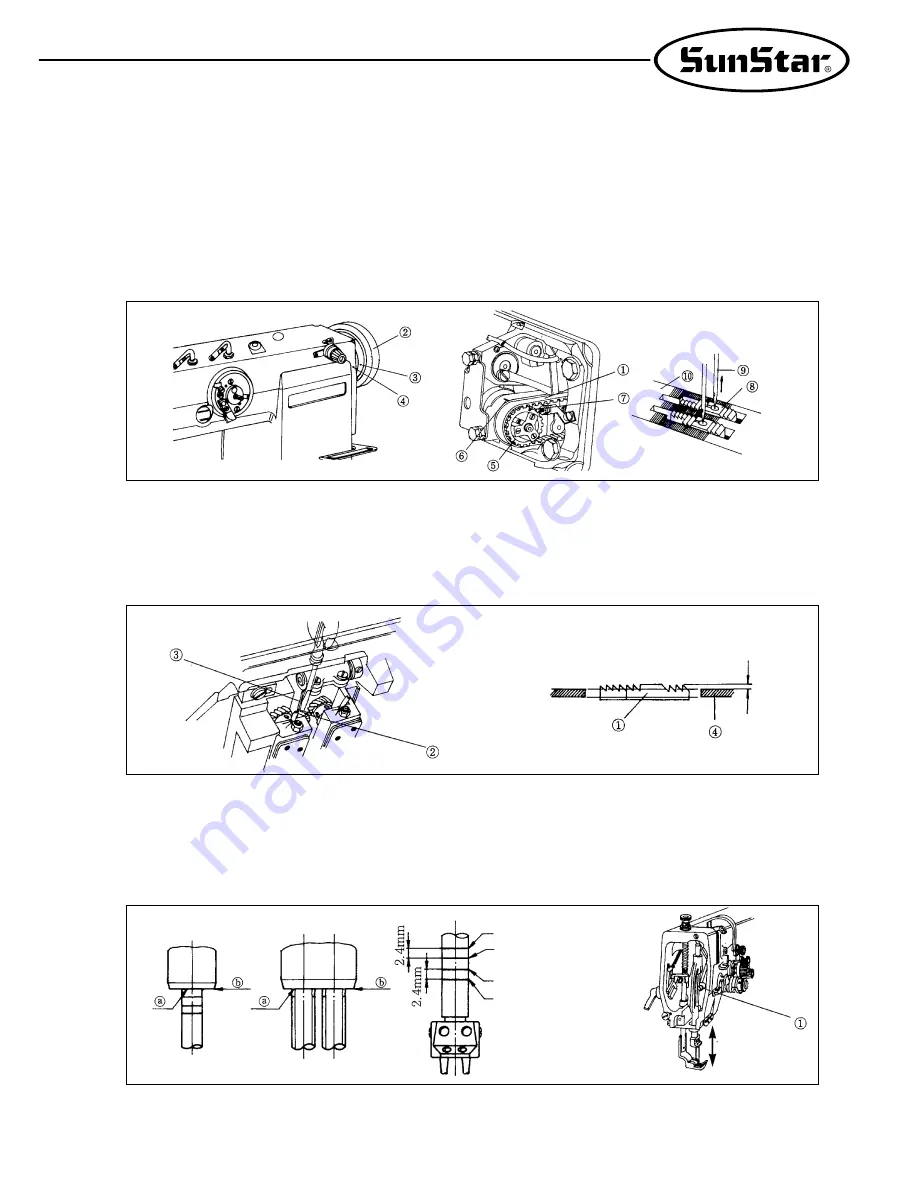

8) Adjusting the needle and feed dog timing

After removing the needle, lay down the machine on its back and remove the timing belt

①

. Turn the pulley

②

to align the

highest position

③

of the pulley

’

s thread take up lever with the position

④

. Then rotate the timing pulley

⑤

to align the bed

base point

⑥

with the timing pulley

’

s base point

⑦

. Hang the timing belt

①

in this position.

After adjustment, when the feed dog

⑧

comes down and the needle

⑨

goes up, check whether the needle tip

⑨

matches the

needle plate upper side

⑩

at the moment that the feed dog upper side and the needle plate upper side

⑩

match each other.

(See figure 30)

9) Adjusting the height of the feed dog

Turn the pulley to place the feed dog

①

in the highest point. Loosen the feed dog base fastening screw

②

and move the feed

dog base

③

up and down to make the feed dog

①

stick out in parallel from the needle plate upper side

④

for about 1 mm.

(See figure 31)

10) Adjusting the needle and hook timing

(1) Fixing the height of the needle bar

Turn the pulley to make the needle bar in the lowest position. Loosen the needle bar holding screw

①

, adjust so that the

needle bar carved sign

ⓐ

meets the end of the frame

ⓑ

like in figure 32, then tighten the screw.

about 1 mm