9

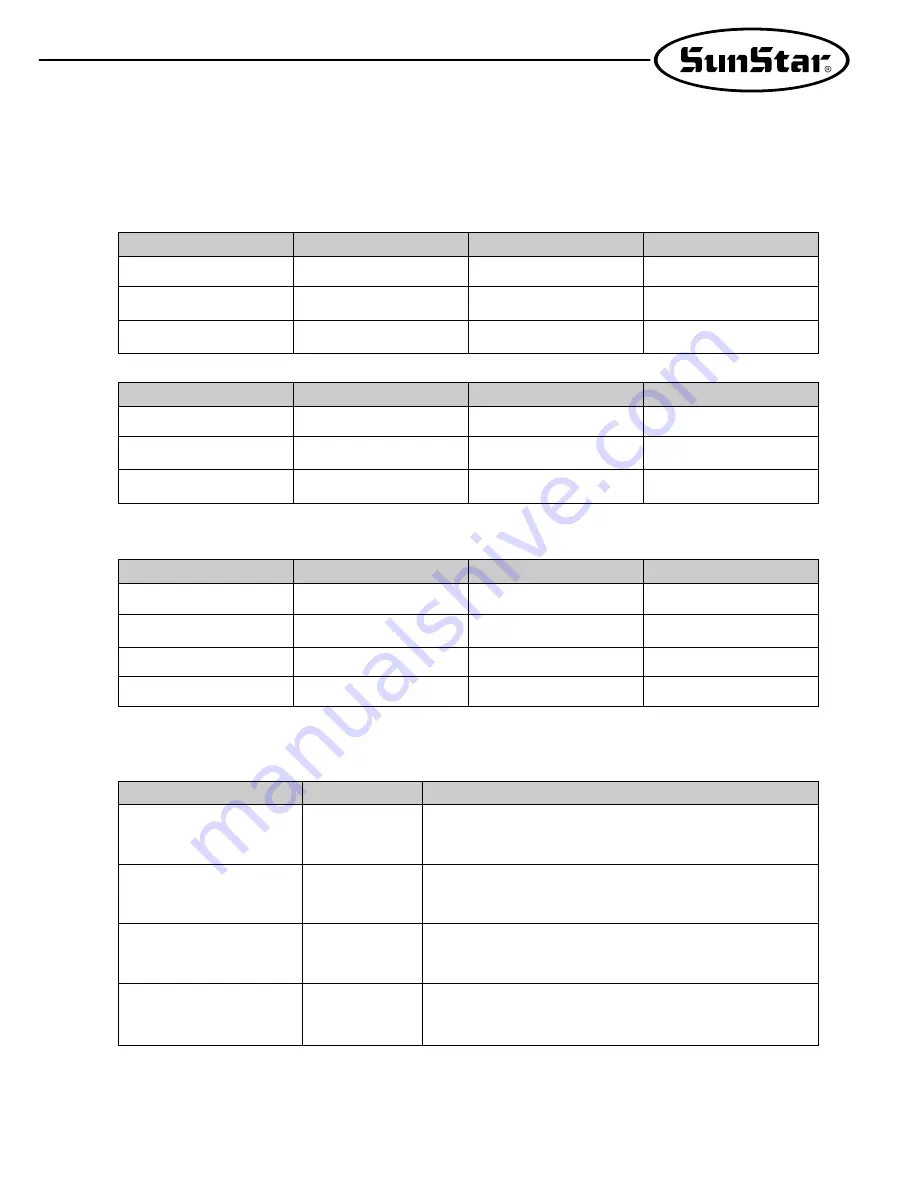

2) Specifications of the servo motor controller

A. KM-750-7, 750BL-7

MODEL

SC55-1B

SC55-2B

SC55-3B

VOLT

1 phase 110V

1 phase 220V

3 phase 220V

WATT

550W

550W

550W

HERTZ

50/60 Hz

50/60 Hz

50/60 Hz

B. KM-790-7, 790BL-7

MODEL

SC55-1C

SC55-2C

SC55-3C

VOLT

1 phase 110V

1 phase 220V

3 phase 220V

WATT

550W

550W

550W

HERTZ

50/60 Hz

50/60 Hz

50/60 Hz

3) Specifications of the clutch motor (for non-trimming type)

MODEL

HEC-1701

HEC-1703

HEC-1705

HEC-1706

VOLT

1 phase 220V

3 phase 220V/380V

3 phase 220V

1 phase 220V

WATT

250W

250W

400W

400W

HERTZ

50/60 Hz

50/60 Hz

50/60 Hz

50/60 Hz

4) Peripheral automation devices (optional: for trimming type)

Purpose

Model

Optional Device

Auto Knee Lifting System

Production Counter

Material Edge Sensor

Standing Pedal

SCOUN-1

SEDG-1B

SEDG-2B

SPDL-1

SPDL-2

A counting device which indicates the completed quantity on the program

unit panel, including added, subtracted, corrected or remaining quantity

along with other performance rates.

A device that senses the edge or thickness of the sewing material to stop

the machine without manual pedaling. Available in two types: SEDG-1B

for edge sensing type and SEDG-2B for thickness sensing type.

A device needed when only one operator runs several sewing machines. Pedals for

acceleration, thread trimming, presser foot and ascending are built separately. There are

two types: SPDL-1 for fixed speed type and SPDL-2, EDPL-2 for adjustable speed type.

SPF-3A

A solenoid operating structure where the presser foot gets lifted

automatically with pedal reverse gear stage 1 operation.