-7-

INSTALLATION TO GAS SUPPLY

1. The gas supply must comply with local codes, or in their

absence, the installation must be in accordance with the

American National Standard (National Fuel Gas Code) NFPA

54, also known as ANSI Z223.1 - latest edition, available

from the ANSI, Inc., 1434 Broadway, New York, New York

10018, or the National Fire Protection Association,

Batterymarch Park, Quincy, MA 02269.

2.

WARNING:

When using LP gas, this heater requires an

external regulator (not supplied) located between the heater

and LP Supply Tank. This regulator must be supplied by the

installer to reduce incoming LP Gas pressure to a maximum

of 14 inches of water column. Under no circumstances

should this heater ever be hooked directly to an LP supply

tank.

IMPORTANT:

The Pressure Regulator must be held

with a wrench when connecting gas piping and/or fittings to

the Pressure Regulator.

3. Use only new, black iron or rust resistant steel pipe. Copper

tubing may be acceptable in certain areas.

CHECK LOCAL

CODES TO DETERMINE ACCEPTABLE TYPES OF GAS

PIPING.

4. The gas supply line shall be sized and installed to provide a

sufficient supply of gas to meet the minimum demand of

the heater without undue loss of pressure.

Typical Installation

Supply Line

Up to 20,000 Btu/hr

3/8" or greater

Up to 30,000 Btu/hr

1/2" or greater

5. The sealant used on the threaded pipe joints of the gas pipe

must be the specific type resistant to the action of Liquid

Petroleum Gas. Apply sealant lightly to male threads to

ensure excess sealant does not enter lines. Any excess

sealant could be forced into the pipe and result in clogged

gas valves.

6. The supply system must include a manual shut-off valve, a

union in the line, and a plugged 1/8" NPT tap. The tap

should be accessible for test gauge connections upstream of

the gas supply connection to heater.

7. Include a drip leg (trap) in the supply line. The purpose of

the drip leg is to prevent moisture and contaminants in the

gas supply from entering the heater controls. The drip leg

should be readily accessible to permit cleaning or emptying.

A drip leg should not be located where the condensate is

likely to freeze. Failure to use a drip leg can result in

operational difficulties in the heater.

GAS SUPPLY CHECK

A union must be provided directly at the gas inlet to the heater.

A manual gas valve must be provided upstream of the union.

This will allow you to shut off the gas supply to the heater if it is

necessary to remove it for service purposes.

The appliance and its appliance main shutoff valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of

1/2 psig. (3.45kPa).

The appliance must be isolated from the gas supply piping

system by closing its equipment shutoff valve during any

pressure testing of the gas supply piping system at test pressures

equal to or less than 1/2 psig. (3.45kPa).

The connectors must be checked and cleaned before assembling

and then wrenched up tight for a gas tight connection. Apply a

soap and water solution to all joints and watch for bubbles to

check for gas leaks.

NEVER USE ANY OPEN FLAME TO CHECK

FOR GAS LEAKS.

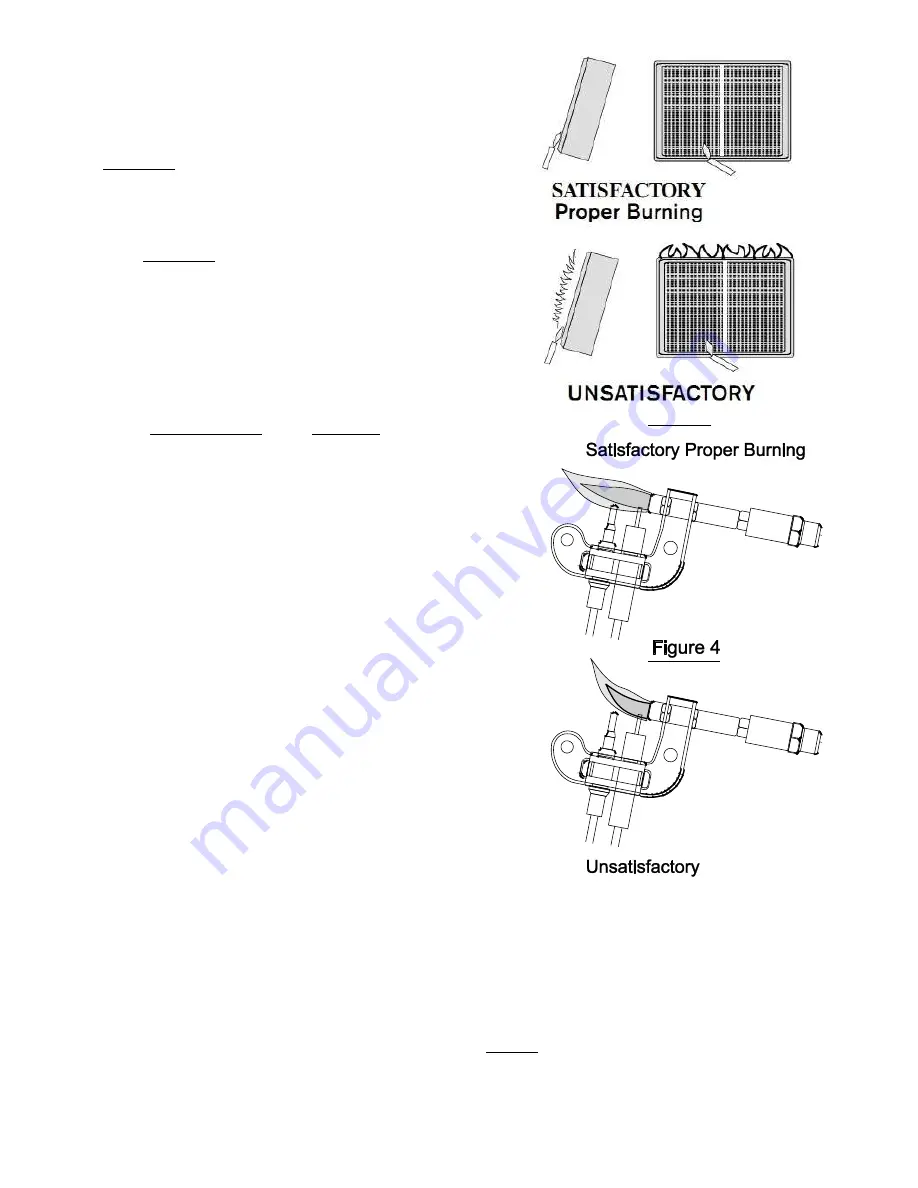

HEATER MAINTENANCE - PERIODIC VISUAL CHECK

The burner must glow evenly over the entire surface when

operating correctly. The pilot flame must burn with a clear blue

flame. See Figures 3 and 4.

HEATER SERVICE

To service the heater, turn off the gas supply and disconnect the

gas piping at the union. Unscrew the two screws located in the

lower front part of the unit. By sliding the panels upwards and

toward the front, the functional elements of the unit are

uncovered.

Periodic cleaning of the unit is required. Dust the surface of the

unit and vacuum clean burner surfaces and the control

compartment.

BURNER

If this heater has an optional blower, disconnect the electrical

connection before servicing the heater (e.g., unplug the blower).

Keep the heater area clear and free from combustible materials,

gasoline and other flammable vapors and liquids.

Figure 3