113

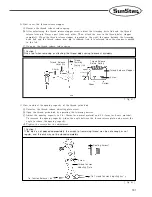

B. Place the winding drive wheel 0.8mm away

from the hand pulley gear and tighten the

screw.

[ Fig. 55 ]

Bobbin Winder

Driving Wheel

Upper Shaft

→

→

0.5mm

13)

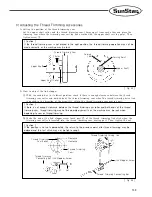

Adjusting the Winding Device

A. To adjust the winding capacity of the bobbin,

use the beginning position of the winding control

plate, and after unfastening the screw, turn the

plate in direction A for large winding capacity

and turn in direction B for small winding

capacity.

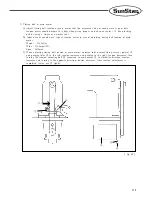

14) Tension Adjustment of Driving Belt

A. Specifications of tension adjuster of each driving belt (sound wave type of belt tension meter)

ⓐ Model Name : U-305 Series Sound Wave Type of Standard Belt Tension Meter

ⓑ Manufacturer : UNITTA

B. X-Axis Timing Belt

ⓐ Check tension of X-axis timing belt by using sound wave type of belt tension meter after separating

belt cover from main body.

ⓑ Adjust tension of X-axis timing belt that the measured value of sound wave type of belt tension

meter should become 38~40kgf when giving impact on the end of feed bracket and center of driving

pulley belt like plucking belt by using a finger or a similar tool.

ⓒ Input data of sound wave type of belt tension meter in case of adjusting X-axis timing belt tension

Weight : 004.0gf/m

Wide : 020.0mm/#R

Span : 0180mm

[ Fig. 54 ]

Bobbin Winder Adjusting Plate

Bobbin

A

B

[ Caution ]

1. If tension adjustment of each driving belt is required, it may affect on embroidery quality and driving of

the machine. Therefore, please perform tension adjustment through service staff of the company or a

equivalent field engineer who received training of the company.

2. In case of tension adjustment of each driving belt, turn “OFF”the power for sure.