114

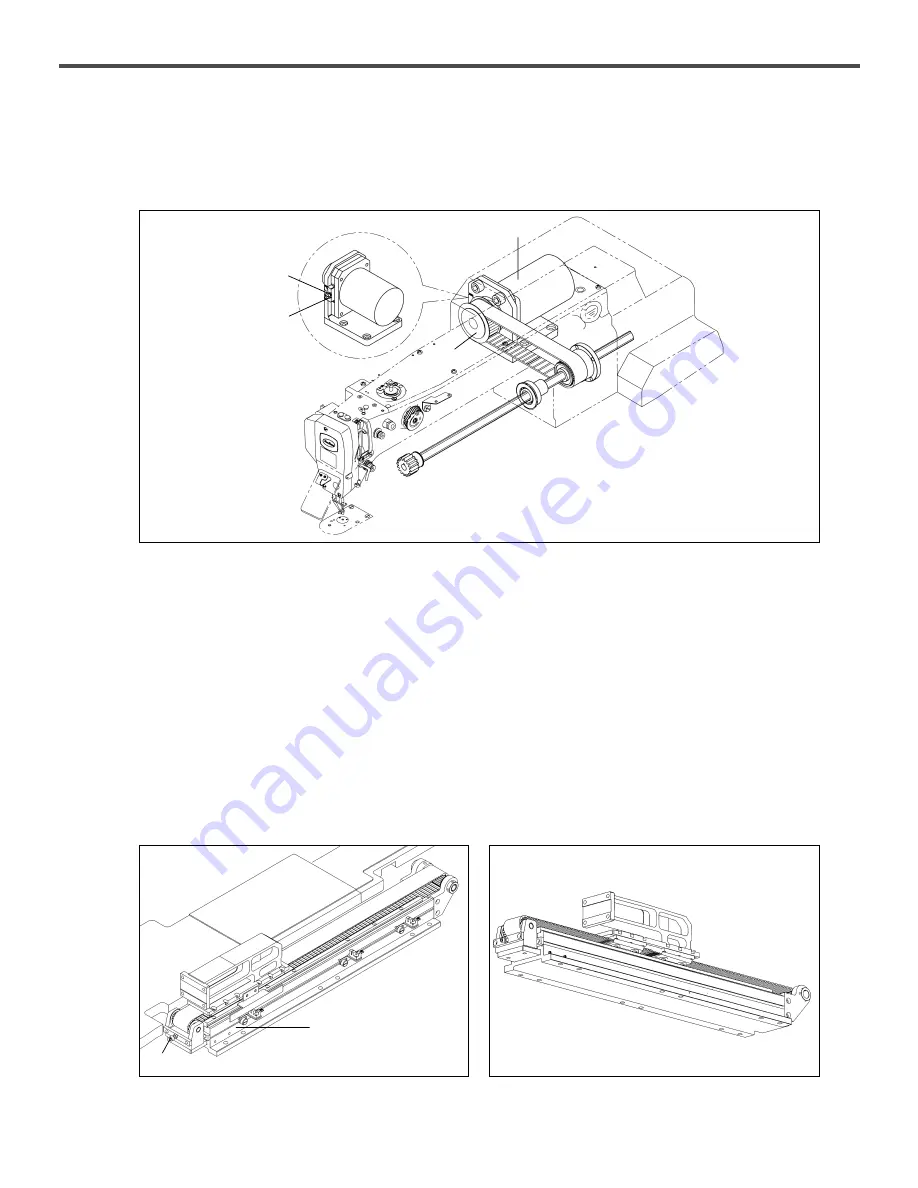

ⓓ In case of adjusting X-axis timing belt tension, first unscrew nut ② connected to adjust bolt ① and

turn the adjust bolt ① to clockwise direction. Then timing belt tension increases while driving pulley

③ and motor ④ being pulled toward volt and turning to counter clockwise direction, belt tension

decreases.

C. Y-axis timing belt

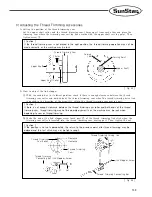

ⓐ In case of confirming Y-axis timing belt tension, confirm by using sound wave type of belt tension

meter after forwarding x-fixing/transfer frame to the maximum as shown in the figure.

ⓑ Adjust tension of Y-axis timing belt that the measured value of sound wave type of belt tension

meter should become 27~28kgf when giving impact on the end of feed bracket and center of driving

pulley belt like plucking belt by using a finger or a similar tool.

ⓒ Input data of sound wave type of belt tension meter in case of adjusting Y-axis timing belt tension.

Weight : 004.0gf/m

Wide : 048.0mm/#R

Span : 0485mm

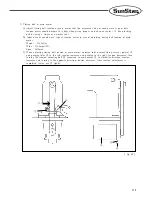

ⓓ In case of adjusting Y-axis timing belt tension, first unscrew tension base joint screw ① and adjust

to proper tension by turning the tension adjusting bolt ②. Turning the tension adjusting volt ② to

clockwise direction, belt tension increases and turning to counter clockwise direction, the tension

decreases.

[ Fig. 56 ]

[ Fig. 57 ]

[ Fig. 58 ]

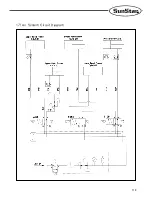

(A)

↓

↓

④

③

②

①

(B)

↓

↓

①

②