29

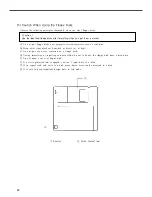

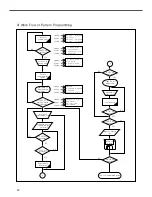

3) Flow Chart of General Operation

Power On

NO

NO

YES

NO

YES

YES

Indication of

general sewing

mode

General Sewing

mode

Is NO key

pressed?

Selection of

pattern No.

Read

disk

Indication of

special working

mode

Selectin of

working mode

0:Initialization

1. S/W Version

2. Para. Init.

3. Sys. UpDate

1:

Parameter setting

0. JOG En/Dis

1. JOG Mode

2. Machine Org1

3. Machine Org2

4. Strt Ret Mod

5. Bobbin Counter

6. Prodct Counter

7. Pattern Read

8. Trim EM Stop

9. Slow Start

10. Max Speed

11. Feed End Pos

12. FF Operation

.

.

◎ Refer the

appendix 3.

2:Pattern

programming

0. TRIM

1. SEC_ORG

2. PAUSE

3. EMPTY

4. JUMP

5. POINT

6. LINE/CURVE

7. LINE

8. CURVE

9. ARC

10. CIRCLE

11. UMP SPD

12. STI SPD

.

.

◎ Refer the

appendix 4.

3:Thread winding

4:Machine test

5:Pattern list

6:Embroidery

data conversion

0. Encoder Test

1. XY Main Test

2. MainMotor Test

3. Interrupt Test

4. PWM Test

5. LCD Test

6. Keyboard Test

7. Input0 Test

8. Input1 Test

9. Input2 Test

10. XY Jog Test

11. Solenoid Test

12. Origin Test

13. Jump Test

0. Memory

1. FDD

0. SWF

1. TAJIMA

Light On for

preparation

Operation of

pedal switch

Sewing

Is ENTER

key pressed?

Is MODE

key pressed?

N O : 0 0 0 N O R _ S E W

X S : 1 0 0 %

Y S : 1 0 0 % S P : 2 0 0 0

B C : 0 0 0 P C : 0 0 0 0

POWER LED

READY LED

ERROR LED

POWER LED

READY LED

ERROR LED

POWER LED

READY LED

ERROR LED

N O : 0 0 0 N O R _ S E W

X S : 1 0 0 %

Y S : 1 0 0 % S P : 2 0 0 0

B C : 0 0 0 P C : 0 0 0 0

< < M a i n M e n u > >

0 . I n i t i a l i z e

1 . P a r a m e t e r S e t

2 . P r o g r a m