24

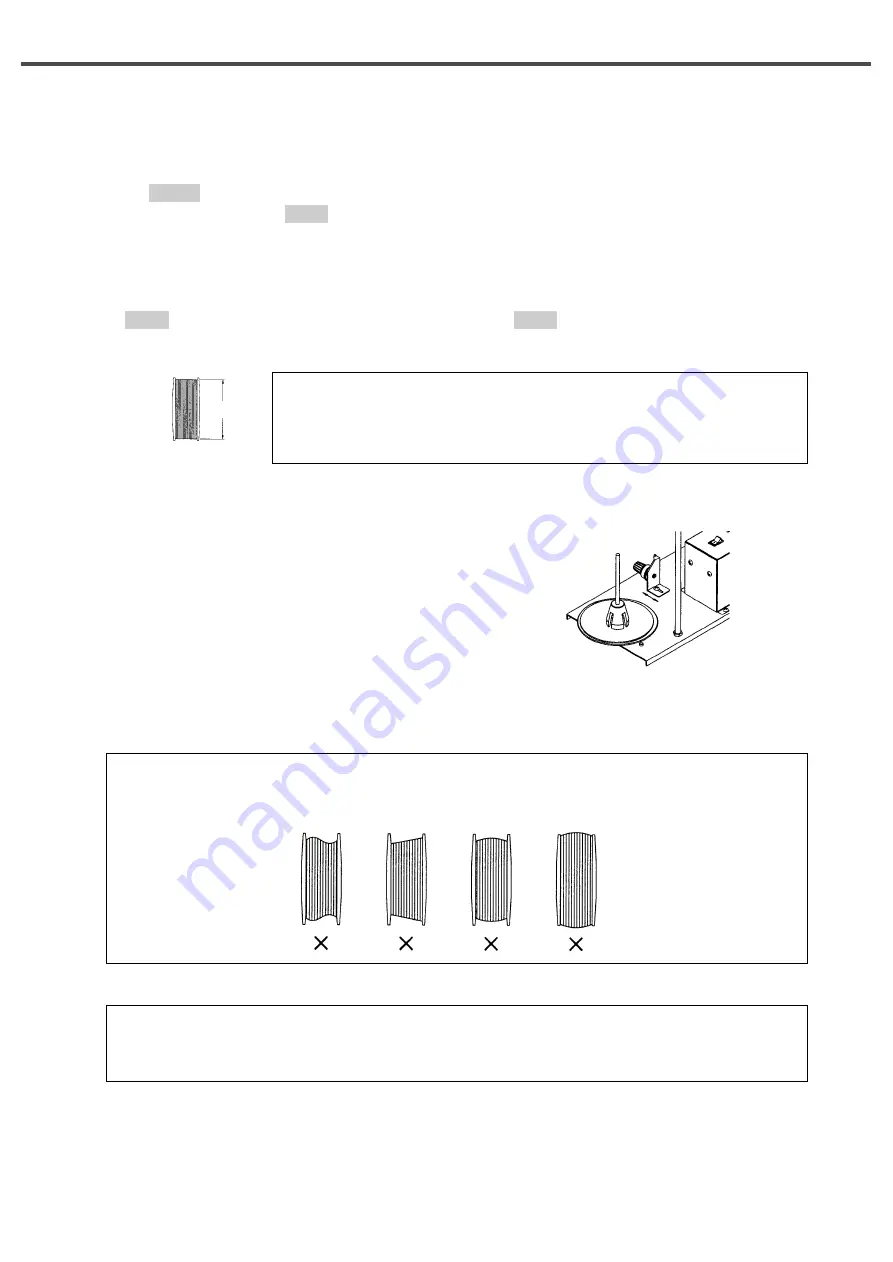

[ Fig. 23 ]

[ Fig. 22 ]

[ Fig. 24 ]

2) Winding lower thread

①

Insert the bobbin into the bobbin winder shaft, wind the thread manually five to six times as bobbin winds it, and then press

the

button. Bobbin turns with winding the thread.

②

Built-in timer automatically

bobbin winder. However, whenever the bobbin needs to stop, press the stop button.

STOP

START

3) Adjusting the amount of thread

①

As in Figure 22, thread should be wound about 80 percent parallel with the bobbin.

②

dial control the amount of thread wound. If the dial turns to

, the amount will increase.

MAX

TIME

4) Adjusting lower thread wind

①

Thread should be wound parallel with the bobbin. If it doesn’t,

unfasten the clamp screw of the thread guide body on the thread

winder and adjust the thread guide body horizontally, as in

Figure 23.

②

Tension of the thread wound can be adjusted with the tension

adjustment nut.

[Caution 1]

If lower thread winds as in the following figures, thread may break, lower thread be skipped, or thread get

tangled, because of the problem with release of the lower thread.

[Caution]

·

If too much lower thread is wound, the lower thread would have a release problem.

·

If the lower thread winds bobbin about 80 percent, it is about 80 meters long for the

standard bobbin.

[Caution 2]

If lower thread winds too strongly, problems may occur like lower thread breaking and shortened lower thread,

because lower thread is not released smoothly.

80%