27

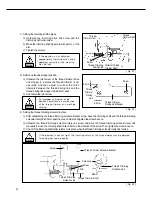

[ Fig. 41 ]

B. Height Adjustment of Presser Bar

Adjust the presser bar that end of presser bar should

come out about 17mm from presser bar handle and

check if the needle passes through center of presser

bar.If checking ends, fasten joint screw

①

.

Presser

Bar

Presser Foot

Presser

Bar Holder

a) Unscrew location link stopper screw to make space between location link stopper

④

and fixing stud screw of

presser foot motion link

③

.

b) After unscrewing fork link joint screw

①

and placing stud screw of presser foot link to the right side of presser

foot adjusting arm, fasten stud screw

②

of presser foot link tightly.

c) Place the needle bar to the lowest point by turning the hand pulley.

d) Raise the presser bar so that the distance between presser bar handle and presser bar bush is to be 4mm and

fasten the joint screw

①

of fork link tightly.

e) Adjust so that location link stopper

④

and fixing stud screw of presser foot motion link

③

get close by turning

stopper screw of location link.

f) After fastening fork link joint screw

①

tightly, check if there is play to vertical direction in presser foot adjusting

arm. Checking fastening status of screws, adjust presser foot stroke.

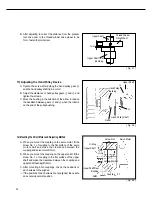

C. Adjustment of Presser Foot Adjusting Arm

Presser Foot Adjusting Arm

①

④

③

9mm

Presser Bar Bush

Presser Bar Holder

②

[ Fig. 42 ]

①

Fasten joint screw ① of presser bar

with the pressure about 40∼45kgf/cm².

If connection pressure is excessive,

it becomes cause of deformation of

presser bar and cause trouble to

machine operation.

Caution

If there is space between presser bar handle and presser bar bush, interference and noise is

occurring during machine operation, screws are not fastened tightly after adjustment; it can cause

breakage during operation.

Caution

If fixing stud screw ③ of presser foot motion link and end of the location link stopper ④

did not get perfectly close, trembling phenomenon occurs during operation and noise can

increase.

Caution

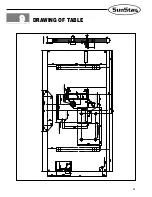

Summary of Contents for SPS/ D-B1254 Series

Page 39: ...39 DRAWING OF TABLE 9 9 ...