33

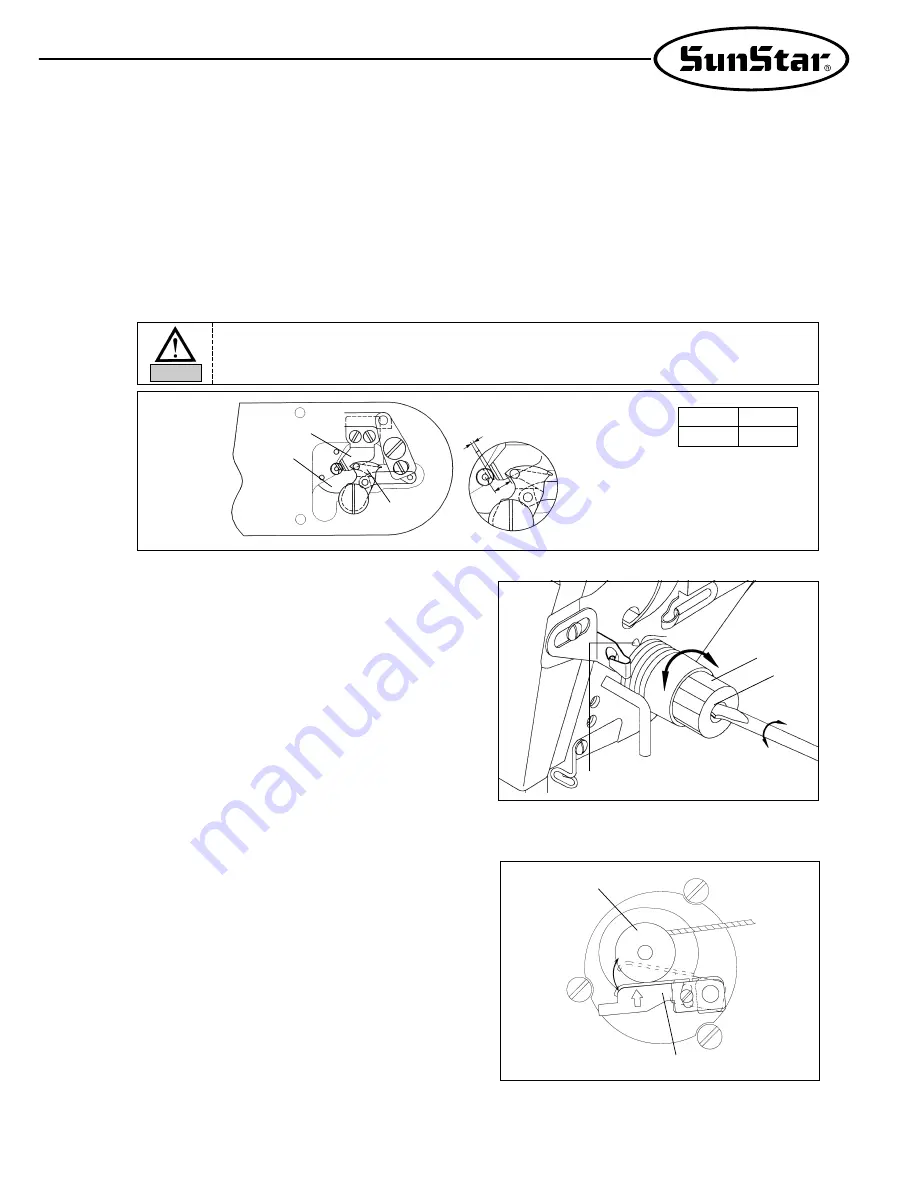

F. Adjusting the Moving Mes and the Fixed Mes

ⓐ

When the meedle bar stops at the upper position, use the trimming lever adjustment screw to adjust space

A

between the thread separation point of the moving mes and the throat plate hole as indicated in the table.

ⓑ

Use the fixed mes screw to adjust space

B

between the fixed plate and the throat plate cover as indicated in the

table.

ⓒ

after the adjustment, check the position of the mes by manual trimming operation.

[ Fig. 54 ]

Moving Mes

Needle Plate Cover

Fixed Mes

B

A

A

4.5

mm

B

0.5

mm

[ Fig. 55 ]

A. When the tension control nut

①

of the thread control

device is turned clockwise, the upper thread is tightened

and becomes loose as the nut is turned counter

clockwise. Adjust the tension according to the sewing

conditions such as material, thread, number of stitches

etc.

B. To tighten the take-up lever spring, use a driver to turn

the groove

②

on the edge face of the thread tension

control device shaft clockwise.

And to make the spring relax, turn it counerclockwise.

(Standard operating quantity 6

∼

8mm, and tension is

about 30

∼

50g.)

11) Adjusting the Devices for MainThread Adjustment

[ Fig. 56 ]

A. To adjust the winding capacity of the bobbin, use the

beginning position of the winding control plate, an after

unfastening the screw, turn the plate in direction

A

for

large winding capacity and turn in direction

B

for small

winding capacity.

12) Adjusting the Winder Devices

Bobbin

Bobbin Winder Adjusting Plate

Weak

Thread Take-up Spring

②

Strong

①

A

B

Trimming may not be operated or there may not be enough remaining thread if the mes

is not set appropriately.

Caution

Summary of Contents for SPS/ D-B1254 Series

Page 39: ...39 DRAWING OF TABLE 9 9 ...