27

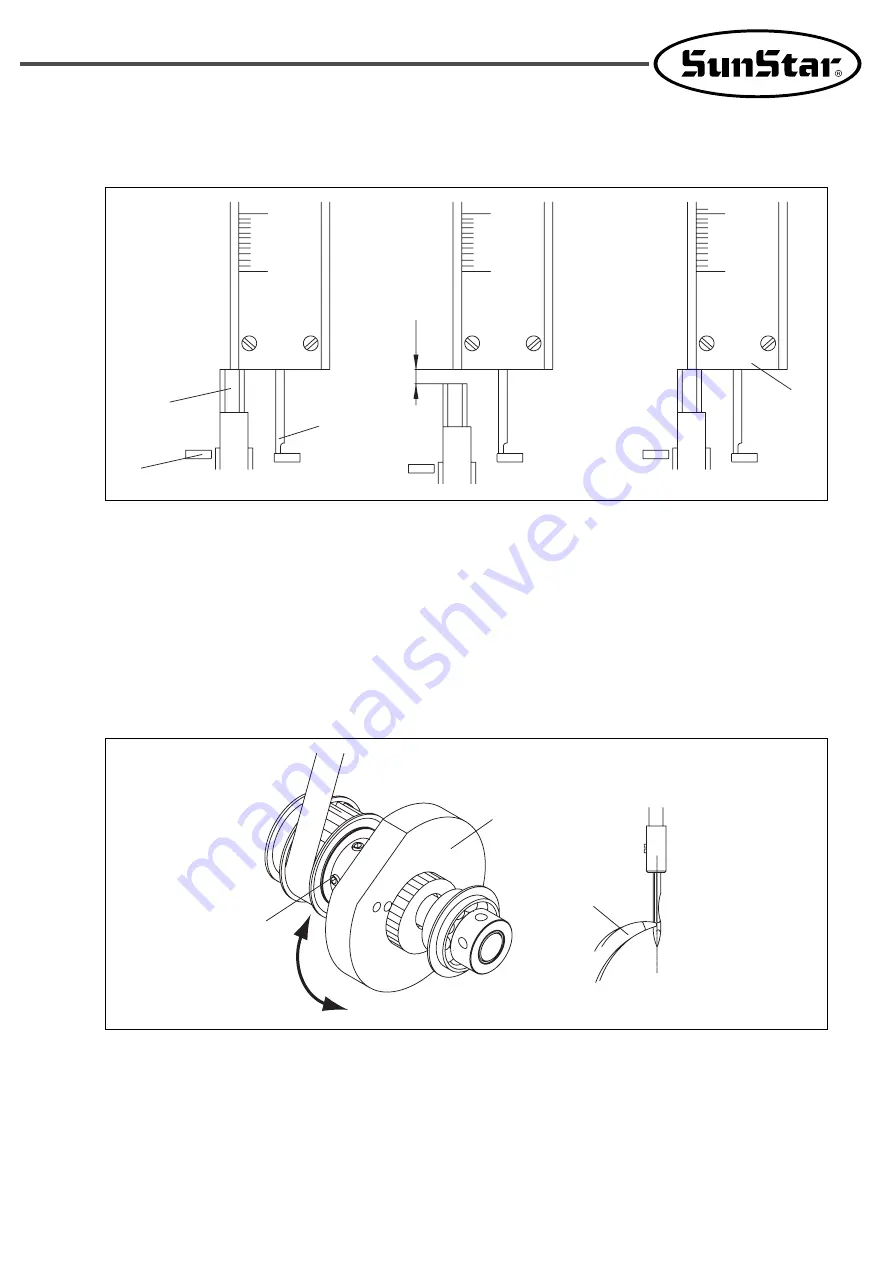

3) Adjust looper stroke

A. Locate the needle bar at the lowest point when the needle is at the left side. Use calipers to measure the distance from the

end of the needle bar

①

to the upper side

②

of the needle bar bracket.

B. Add 3mm to the value measured in A.

C. Make the end of calipers (A) contact the upper side

②

of the needle bar bracket. Turn the upper pulley to make the end of

the needle bar

①

contact the edge of calipers(B). Check whether the end of the left looper is touching the center of the

needle.

D. Repeat the above procedures to check whether the end of the right looper is touching the center of the needle in case

where the needle is at the right side.

E. If the end of the looper doesn

’

t meet the center of the needle, lift the body of the machine.

F. Loosen the two screws

③

of the lower axle timing belt, hold the hand pulley to fix it and then turn the lower cam in the

direction of the arrow to make the end of the looper (left)

⑤

contact the center of the needle. When they are matched,

tighten the two screws

③

.

G. Check if the right degree of pressure is put on the screws.

[ Fig. 29 ]

[ Fig. 30 ]

①

③

④

⑤

②

(A)

(B)

3mm

Summary of Contents for SPS/D-BH-6000 Series

Page 37: ...37 8 8 Table Drawings 1 Basic ...

Page 38: ...38 2 Optional Mountable on the table ...

Page 42: ...42 1 10 0 Air System Circuit Diagram ...

Page 43: ...43 ...

Page 44: ...44 Optional Devices ...