28

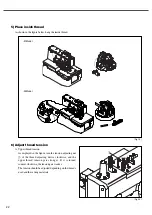

4) Adjust the height of needle bar

A. When the needle

①

is within the sewing zone, adjust the center of the needle and the end of the looper (left)

②

to meet

together.

B. Release the screw

④

of the needle bar clamp

③

and adjust the height of the needle bar.

C. Make adjustment to enable the needle bar clamp

③

and the needle bar horizontal link

⑤

to maintain their own oil layers

respectively.

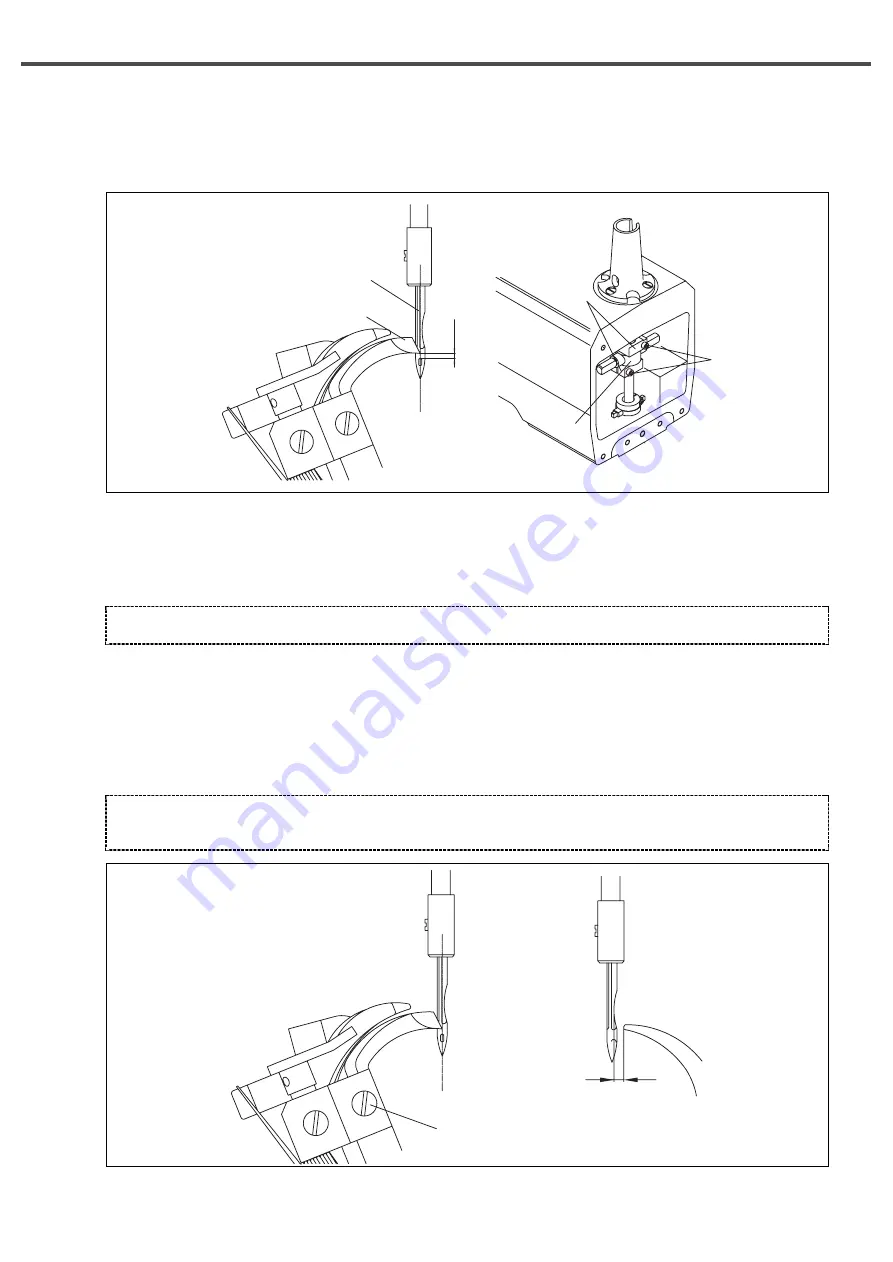

5) Adjust the distance between needle and looper

Loosen the looper screw

①

to adjust the distance between needle and looper at the range of 0.05~0.2mm, and then tighten the

screw

①

again.

[ Fig. 31 ]

[ Fig. 32 ]

Make the end of the looper (left)

②

meet the upper edge of the needle hole and lower the needle bar by 2mm.

[ CAUTION ]

Although the looper base turns 360

°

, the distance between needle and looper should be same.

①

③

④

⑤

①

0.05~0.2mm

②

2mm

Summary of Contents for SPS/D-BH-6000 Series

Page 37: ...37 8 8 Table Drawings 1 Basic ...

Page 38: ...38 2 Optional Mountable on the table ...

Page 42: ...42 1 10 0 Air System Circuit Diagram ...

Page 43: ...43 ...

Page 44: ...44 Optional Devices ...