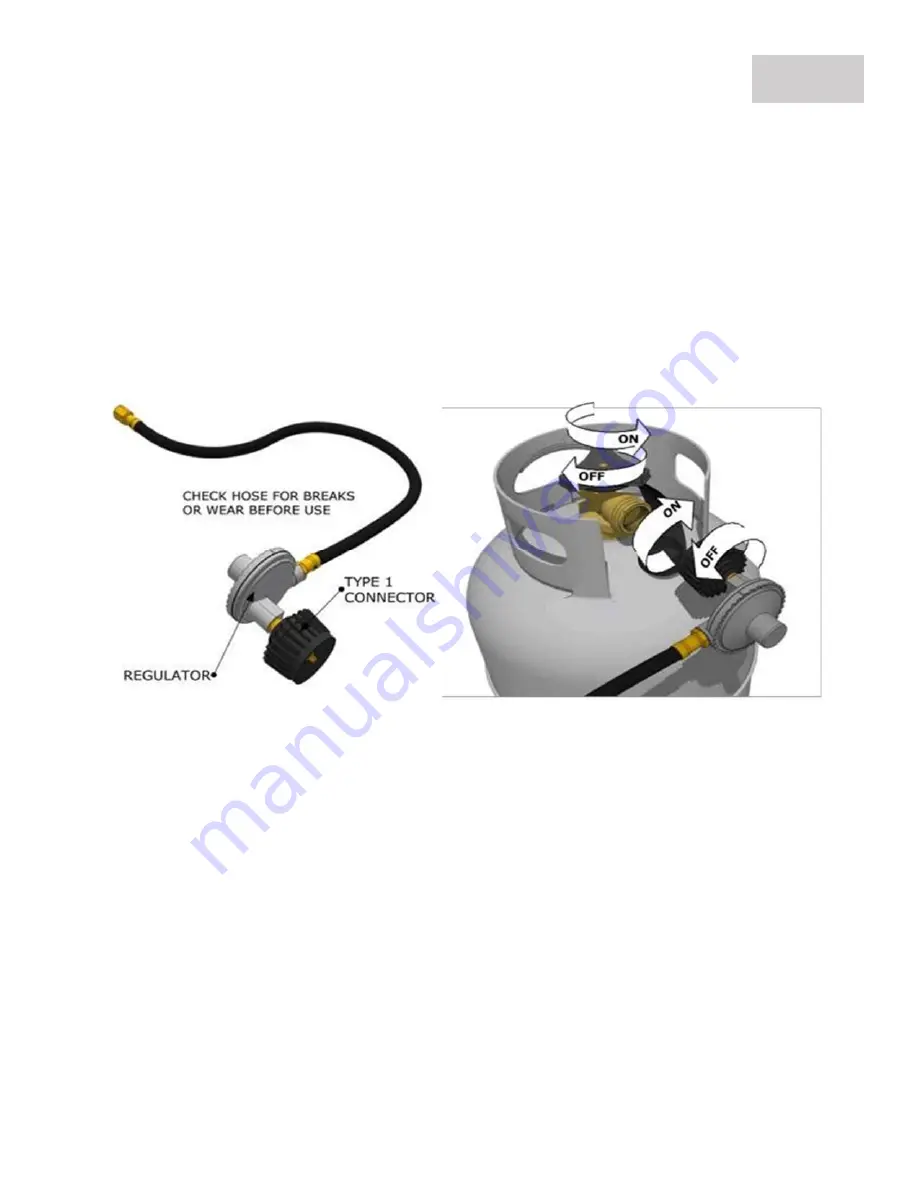

Medium Capacity LP Tank

The Type 1 connection system has the following features: The system will not allow gas to flow

until a positive connection has been made. NOTE: The cylinder control valve must be turned off

before any connection is made or removed. The system has a thermal element that will shut off

the flow of gas in the event of a fire. The system has a flow limiting device which, when activated,

will limit the flow of gas to 10 cubic feet per hour. NEVER use grill without leak testing.

GAS SETUP – MEDIUM CAPACITY LP TANKS

PAGE 12

Follow Instructions:

The tank valve & all Knobs should be in the “OFF” position. If not, turn the knob clockwise until it

stops.

Insert the regulator inlet into the tank valve and turn the coupling nut clockwise until the coupler

tightens up (see picture above). Do not overtighten the coupler. Turn the main tank valve on and

turn the grill control valves on the unit to the “HIGH” position for about 20 seconds to allow the

air in the system to purge before attempting to light the burners.