32

INSTALLATION and OPERATION MANUAL

INSTALLATION and OPERATION MANUAL

INSTALLATION and OPERATION MANUAL

INSTALLATION and OPERATION MANUAL

which is the time between two fuel sup

-

ply periods, are set. In order for the fire

to burn properly, an appropriate amount

of air must be supplied. Therefore, the

speeds of the main fan (row

Fan

) and the

chimney (row

Chimney vent

) must also

be set.

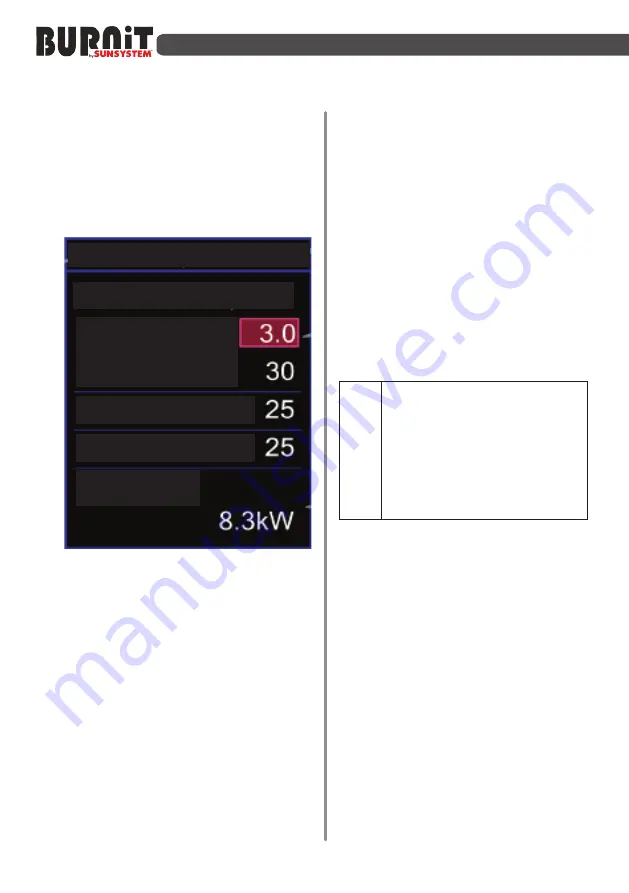

D1>Power P1

Power

Chimney fan

Fan

Fuel supply

Serving (sec)

Cycle (sec)

Power field

- Calculated power based on

calorific value 5kWh / kg.

This parameter is not corrected!

We recommend that you set the P3

power to the maximum power you will

want to receive from the burner. Power

P2 should be 50% of P3 and P1 should

be 20% of P3. With such a setting, the

controller will be able to smoothly mod

-

ulate the burner power in the range of

20 to 100%, changing the power if nec

-

essary for each new cycle. For example,

if you need 75% power, the controller

will switch from power P3 to P2 and then

back to P3 at regular intervals. Thus, the

average power can be reduced to the fol

-

lowing (100 + 50) / 2 = 75. The switch

-

ing time will depend on the inertia of

the whole system and the set tempera

-

ture differences in the menu

"Service

settings" -> "Power modulation"

. The

smallest interval for switching between

two powers can be one cycle, which is

about 20-30 seconds. For such a short

switching period, the temperature of the

heating system will not change signifi

-

cantly to feel the pulsation of power. By

adding

"Maintenance"

power, which will

be less than P1, the burner gets an even

wider range of modulation.

It is important when adjusting

the

maintenance

power

parameters, not to allow such

an increase in the cycle between

two pellet feeds that the

available pellets in the upper

chamber burn and do not leave

enough heat to ignite the next

pellets!

Intermediate Cleaning -

This menu sets

an additional feature that the NPBC-V3C

controller allows, called "Intermediate

Cleaning". The idea is that while the

burner is operating normally, only in

-

crease the speed of the fans, which will

temporarily raise the temperature of the

fire and this will lead to a more complete

combustion of slag and ash. A mechani

-

cal cleaning mechanism connected to

the FC outlet can also be used, which can

be activated periodically while the fire

is burning to scrape off the stuck slag or

ash.

T

o do this, you need to check the

"Exit FC"

line and perhaps remove the

"Change vent"

line.