IOM-WR-TapeMat 1526

14 of 32

STEP 3.7

Use a digital multi-meter to measure the

resistance between the conductors of the

power leads again. Record these resistances in

Table 4

under “After mat is secured in place”.

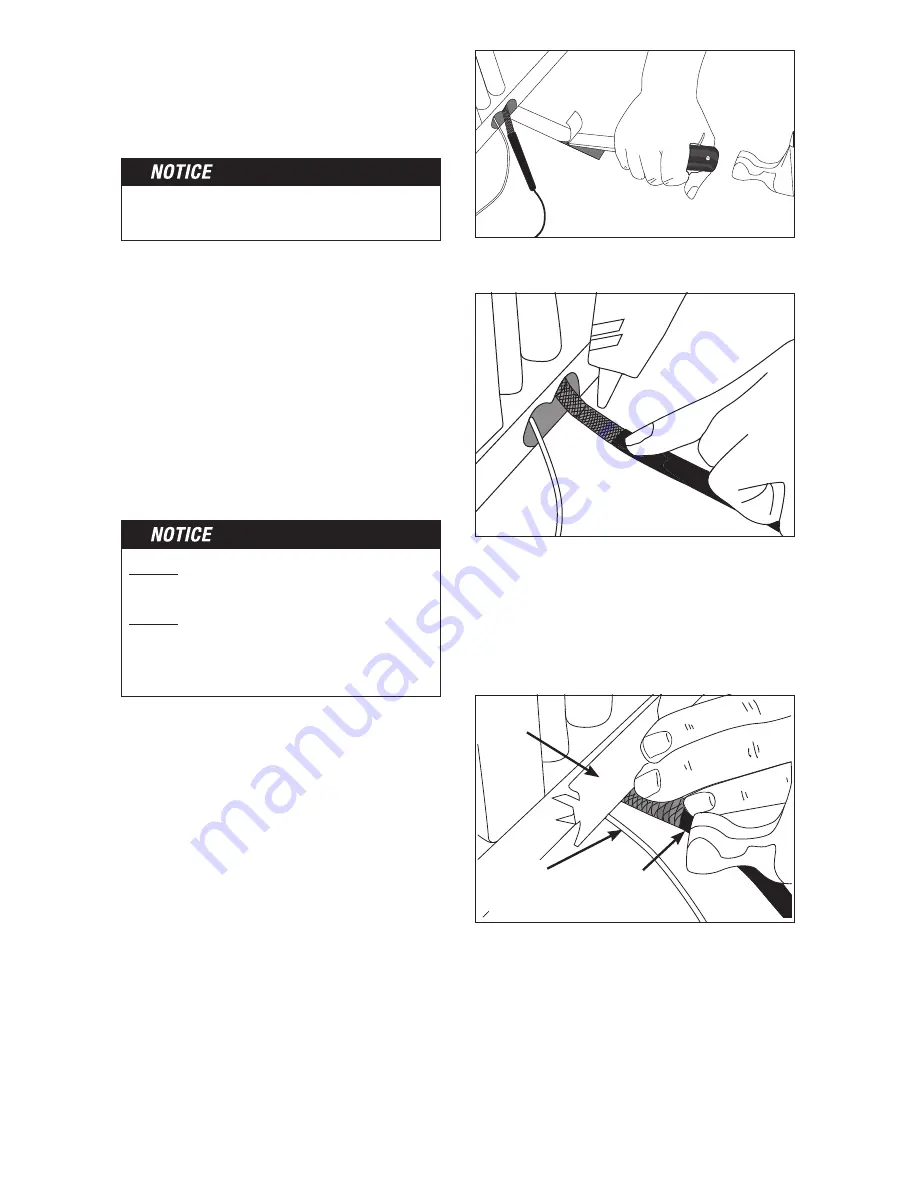

STEP 3.8

Feed the power leads through the conduit

to the control electrical box, leaving at least

6"-8" of free power lead. Chisel a slot in the

floor to recess the factory splice level with the

heating wire. Secure the factory splice with hot

glue so it cannot be pulled into the conduit.

Chisel a path for the power

lead and factory splice.

Use hot glue to secure to the floor.

Place a metal nail plate over the transition point

to protect the power lead and sensor wire.

Power Lead/

Heating Wire

Connection

Nail

Plate

Floor

Sensor

Wire

Securing the mat as flat as possible will help

make a smooth surface for spreading mortar.

DO NOT

staple or apply tape over the heating

wire. Damage can result.

DO NOT

use nails, duct tape, other types of

tape, or other unapproved fasteners

to hold the heating wire or mesh

in place. Damage can result.

If the mat comes with double-sided tape

already attached, remove the liner along one

edge and press the tape down. Remove the

liner along the other edge and press the tape

down, pulling lightly on the mat to keep it flat.

Ensure all edges of the mat are secured to

the floor using double-sided tape or hot glue.

Secure as needed across the middle of the

mat to ensure the it stays flat during floor

mortar application later. Do not use staples

or anything else that will cause damage to

any waterproofing membrane.

STEP 3.6

Secure the Mat to the Floor

Lay the mat down flat. Ensure it fits well and

has no folds or large ripples.

It may be necessary to use a metal nail plate

to protect the power lead and sensor wire

as they transition into the wall. This will help

prevent nail penetrations from drywall and

baseboards trim.