4

SunTouch TapeMat Installation Manual

Phase 1: Designing the System

SunTouch TapeMat should be installed in all interior floor

areas intending to be warmed. It cannot be used for exterior

applications, snow melting, or in ceilings. In many applications

it can be used to heat the room but an accurate heat-loss

calculation must be made to determine if enough heat will be

provided to match the heat loss.

STEP 1.1

Make a sketch of the room and measure the overall room size.

Measurement should be made from wall-to-wall and include

size and location of cabinets, tub, toilets, etc. Determine

the total square footage of floor area to be warmed by

subtracting out the area associated with the built-ins. Keep in

mind the following:

• Heat will not radiate beyond about 1-1/2" on either

side of the heating wire, therefore consistent coverage

is important.

•

Do

install heating wire within about 1-1/2” to 2” from a

counter or vanity in the kick-space to ensure warmth in

this area.

•

Do not

install the heating wire underneath cabinets or

fixtures having no floor clearance or inside a wall. Excessive

heat will build up and cause damage.

•

Do not

run the heating wire into small closets or other

confined areas where excessive heat will build up.

•

Do not

install the heating wires closer than 6" from toilet

rings to avoid possible melting of wax rings.

•

Do not

directly cross expansion joints.

•

Do not

place the heating wire any closer than 4" from other

items such as forced air ducting or potable piping to avoid

overheating them.

• TapeMat must be laid in a manner to prevent surface

obstructions being placed directly over the mat location.

Failure to do so will result in capturing heat and may allow

potential damage from mounting brackets, bolts, or similar

penetrations associated with pedestals, support columns,

walls, or similar.

• Install the heating wires 4" to 6" away from the perimeter

walls of the room. It may be placed closer, but is

unnecessary since most people do not stand this close to

the wall. Make sure the heating wire will not be located

underneath finish trim.

• The heating wire and factory splices must be completely

embedded in the thin-set. Only the power lead may

exit the thin-set and enter the wall. Pull power leads

through UL Listed conduit to a UL Listed junction box or

the control box.

STEP 1.2

Multiply the heated area square footage calculated in Step 1.1

by 0.90 to allow 4" to 6" spacing around the edges of the floor

area. Use this resulting square footage to select the appropriate

mats from Table 2 on page 5.

Remember:

•

Do not

exceed 15 amps at 120 VAC (1800 watts) or

15 amps (3600 watts) at 240 VAC through a single SunStat or

SunStat Relay.

• Select either 120 VAC or 240 VAC depending on the power

available.

DO NOT

mix voltages on the same SunStat if more

than one mat is to be installed to cover an area.

• Load no more than 12 amps on a 15-amp circuit breaker, or

16 amps on a 20-amp circuit breaker.

• If the area requires more than 15 amps to be controlled by

one thermostat use SunStat Relays to take the additional amp

load.

• See the Wiring Diagrams in Appendix for further information.

If the exact size of product calculated is not found in the

selection Table 2 on page 5, it may be necessary to adjust the

warming area(s) or select the next smaller size.

Remember, the

heating wire must never be cut shorter to fit, and must be

completely embedded in thin-set, thick-set, or self-leveling

concrete. Failure to do so may result in damage to the

product. Do not select a product larger than necessary.

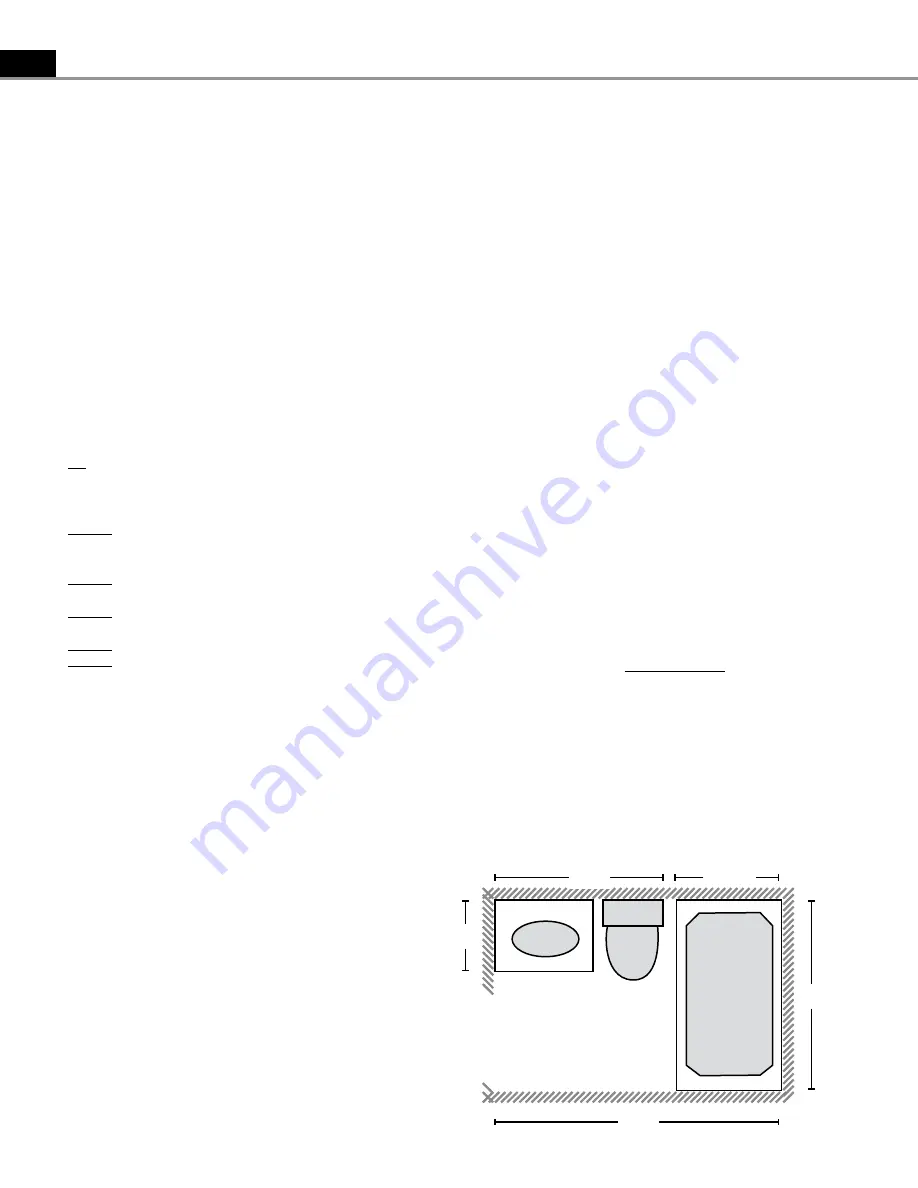

Small bath design

Gross Room Area: 8 x 5 = 40 sf

Built-in Areas

Sink and Toilet: 2 x 5 = 10 sf

Bath Tub: 2.5x 5 = 12.5 sf

Total Heated Area: 40 - (10 + 12.5) = 17.5 sf

TapeMat Coverage: 17.5 x 0.90 = 15.75 sf

Chosen TapeMat Size: 15 sf.

Sink

Toilet

Bath Tub

8 ft

5 ft

2-1/2 ft

5 ft

2 ft