20

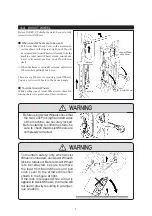

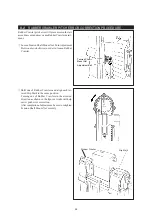

Brake Lever

Assist Wheel

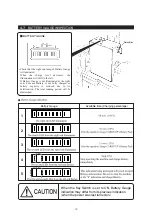

Model SF:

Assist

Handle

Handle Unit

「

ON

」

7-2

GROUND TRANSFER

①

Apply the brake for ground transfer.

②

Before starting ground transfer, be sure to extend

Assist Wheels to maintain safety. Pull the handle

carefully to Assist Wheel's side to tilt the machine

as below.

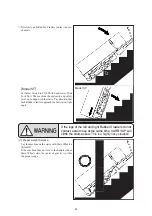

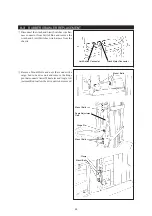

[

Model SF

]

In case of Model SF, at first down Slide Fork Unit

carefully, then the machine is tilted easily.