171

4.5.7 Every 500 hours service

Carry out EVERY 50 HOURS SERVICE and

EVERY 100 HOURS SERVICE at the same time.

4.5.7.1 Greasing ball track of swing bearing

Stop the machine at level ground, lower the

bucket at level ground.

Shut auto-idle speed switch, run the engine

unloaded at low speed for 5 minutes.

【Important】

Stopping the engine improperly may

damage turbocharger.

Set start key to OFF position, stop the engine,

remove the key from starting lock, set safety

lock lever to LOCK position.

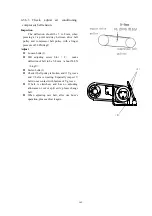

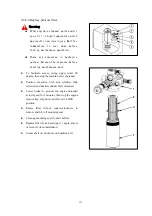

Pump in grease through 3 grease fittings to

swing bearing ball track.

Start engine, lift bucket, and swing

upper-structure at 45 degree.

Repeat 3 times from step 3 until lubricating

grease overflows from swing bearing seal.

Summary of Contents for SWE150F

Page 19: ...12 18 No unauthorized access label Warning Stay clear of operation area of working device...

Page 22: ...15 23 Gravity label 24 Hydraulic oil label 25 Greasing...

Page 151: ...144 4 4 9 Hose...

Page 193: ...186 5 Technical specification...

Page 197: ...190 5 1 4 Circuit diagram...

Page 199: ...192 5 1 6 Hydraulic diagram...

Page 204: ...197 5 2 4 SWE210F Circuit diagram...

Page 206: ...199 5 2 6 Hydraulic diagram...