175

4.5.8.3 Change return filter

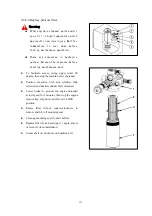

Warning

After the engine is stopped, parts and

oil are still in high temperature

which may result in serious burns.

Wait for temperature to cool down.

There is pressure inside hydraulic

oil tank. Release pressure before

opening oil fill cap located on top of

hydraulic oil tank.

To facilitate access, swing upper turret 90

degree, then stop the machine at level ground.

Position excavator with arm cylinder fully

retracted and bucket cylinder fully extended.

Lower bucket to ground, run engine unloaded

at low speed for 5 minutes, then stop the engine,

remove key, set pilot control lever to LOCK

position.

Clean up upper hydraulic oil tank to prevent

dirt getting into hydraulic system, press down

lock cap to release internal pressure.

Clean up upper hydraulic oil tank to prevent

dirt getting into hydraulic system, press down

lock cap to release internal pressure.

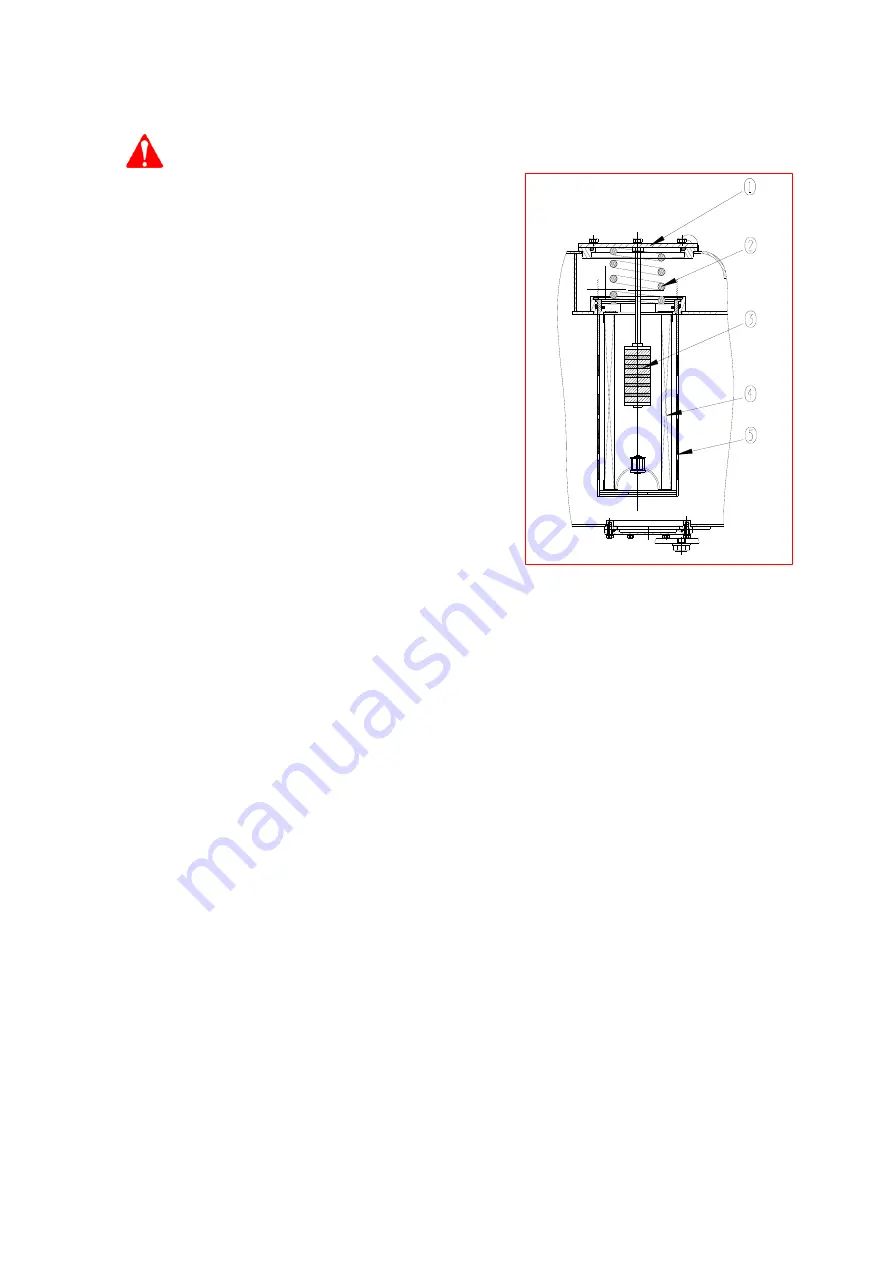

Pull out upper end of bar (3), remove spring (2)

and filter (4).

Check bottom filter shell for dirt, if any dirt is

found, remove it. Pay attention not to let any

dirt get into hydraulic oil tank.

Place removed parts into fresh diesel oil or

washing oil to rinse (except filter), replace with

new filter.

Reinstall filter (4), insert it to the bulge (5) in

oil tank.

When installing, the bulge under cap (1) must

secure spring (2), then use bolt to fasten it.

Summary of Contents for SWE150F

Page 19: ...12 18 No unauthorized access label Warning Stay clear of operation area of working device...

Page 22: ...15 23 Gravity label 24 Hydraulic oil label 25 Greasing...

Page 151: ...144 4 4 9 Hose...

Page 193: ...186 5 Technical specification...

Page 197: ...190 5 1 4 Circuit diagram...

Page 199: ...192 5 1 6 Hydraulic diagram...

Page 204: ...197 5 2 4 SWE210F Circuit diagram...

Page 206: ...199 5 2 6 Hydraulic diagram...