OPERATION & MAINTENANCE MANUAL SWE18UF

27

Check the torque of detectable fastener.

(refer to the torque specifications of fastener in the

maintenance part)

3.2.4 After first 100 hours of operation

Carry out 50-hour and 100-hour maintenance. (refer to maintenance guide....50 hours and

100 hours)

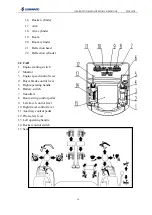

3.3 OPERATING ENGINE

3.3.1 Daily Inspection

1)

Electrical system

Check whether there are abraded or cracked wire and

slack connector or not, and check whether the light

can be turned on or off normally.

2)

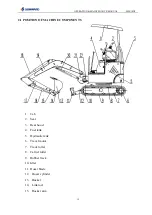

Boom, arm, bucket, dozer blade, sheet metal,

track shoe

Check whether there are curving, damaged and lost

parts or not.

3)

Fastener

Check whether there are slack or lost parts or not.

4)

Fuel system

Drain water and sediment from the fuel tank.

5)

Hydraulic system

Check leakage, hose twist, abrasion between pipes and

hose or other parts.

6)

Lubrication

Check the appointed lubrication points listed in the

periodic maintenance table.

7)

Protection device

Check backplate and mud fender.

8)

Safety

Keep all people away from machine and remove barrier.