78

Check track lag

…every 50 hours (or when necessary)

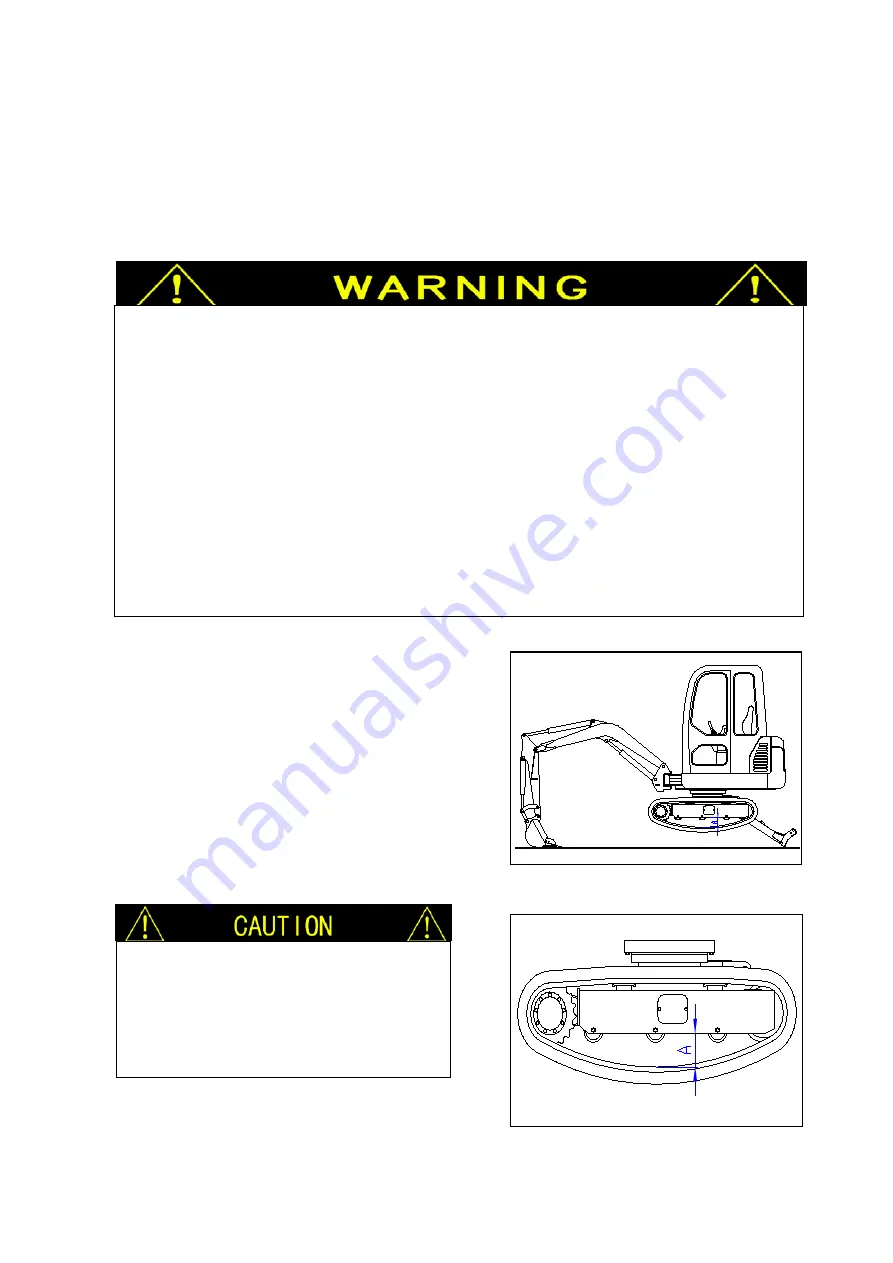

A. Inspection

1).

Slowly operate the control valve, use the

operation device and dozer blade to lift the

machine.

2).

Check the center under surface of the track frame

and the clearance of the up surface (A), the

clearance should be within following range: A

65~70mm.

Please use wood block, jack or other firm and stable supporter to lift the machine.

Never work while there is not enough support of the machine, especially when the

hydraulic cylinder is working.

There is pressure grease in the track tightening mechanism, the grease pressure relief

valve may fly out and cause damage if you do not operate as the follow procedures.

Slowly screw off the grease pressure relief valve.

Never let your body, face, legs or arms be exposed in front of the grease pressure

relief valve.

Two men are needed when checking the track tensity, one operate the excavator to lift

the track of one side, the other one measure the dimension, you must pay more attention

to prevent the sudden movement of the machine. Warn up the engine before the checking

work and park the machine on a level ground, and use stoppers if necessary.

FIG.4-28

If there is too much dirt, dust or other

things on the undercarriage assembly, you

may get an incorrect measure result, so you

must clean the undercarriage before the

measuring work.

FIG.4-2

Summary of Contents for SWE20F 2019

Page 101: ...99 8 ATTACHMENT 8 1 20FNELECTRIC DRAWING...

Page 102: ...100 8 2 20FHYDRAULIC DRAWING...