MAINTENANCE

ROUTINE CHECKS

Hoists

Look for fraying of the hoists at flexion

points like the hoist pipe eye, which can

indicate that they are ready for

replacement. They should last a long time

with normal use, and if they look to be in

sound condition then there is no need to

change them.

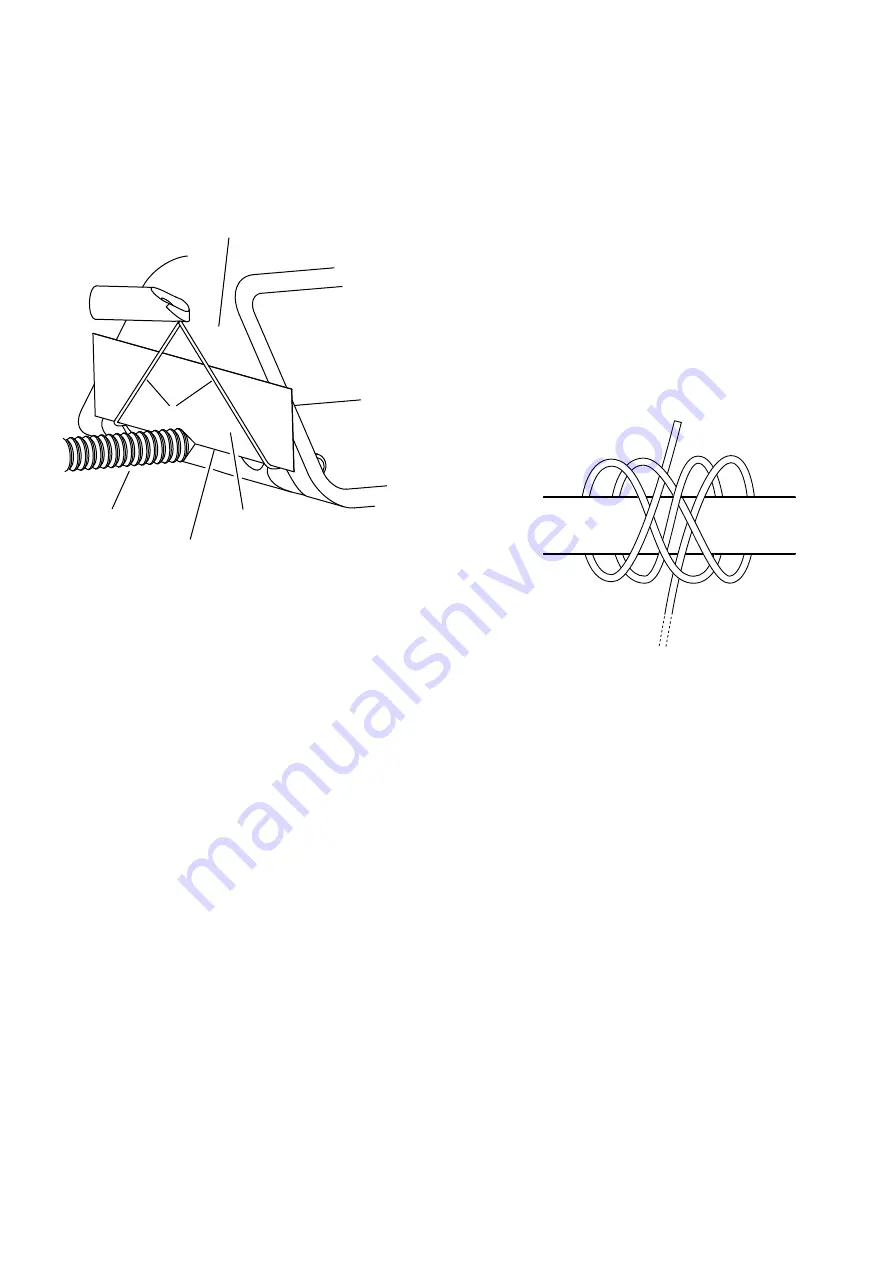

When replacing hoists, use the bend of a

slip knot around the hoist toggles, and a

boom hitch around the spools.

Pivot point

It is not clear whether or how a severely

blunted pivot point might compromise

performance, since pressure against the

pivot is always maintained by gravity.

However, it is very easy to replace the pivot

bolt with a newly-sharpened one. Contact

Supatrac for more information.

Thrust Box Bolts

After long periods check that the bolts

which attach the arm to the thrust box are

17

boom hitch

IMPORTANT: there is a correct height for

the suspended arm: the pivot point must

make contact with the thrust box on the

straight line between the two points

where the hoists meet the thrust box.

To ensure this, cut a 6cm by 1cm rectangle

from the corner of a straight-edged piece of

paper, insert it between the hoists and the

thrust box and raise the headshell so that

the paper’s straight edge sits on the points

where the hoists meet the thrust box. The

pivot contact should occur at or just below

the paper’s edge.

Once the correct height is set, lean can be

adjusted by shortening and lengthening the

two hoists in equal and opposite measure so

that the pivot contact remains on the line

between the suspension points. Always

check that the pivot contact lies on this line

after adjustments by resettling the

suspension and applying the paper test

again. A period of incremental adjustments

to suspension height may help to establish

optimal performance.

16

pivot bolt

straight edge

paper

hoists

thrust box