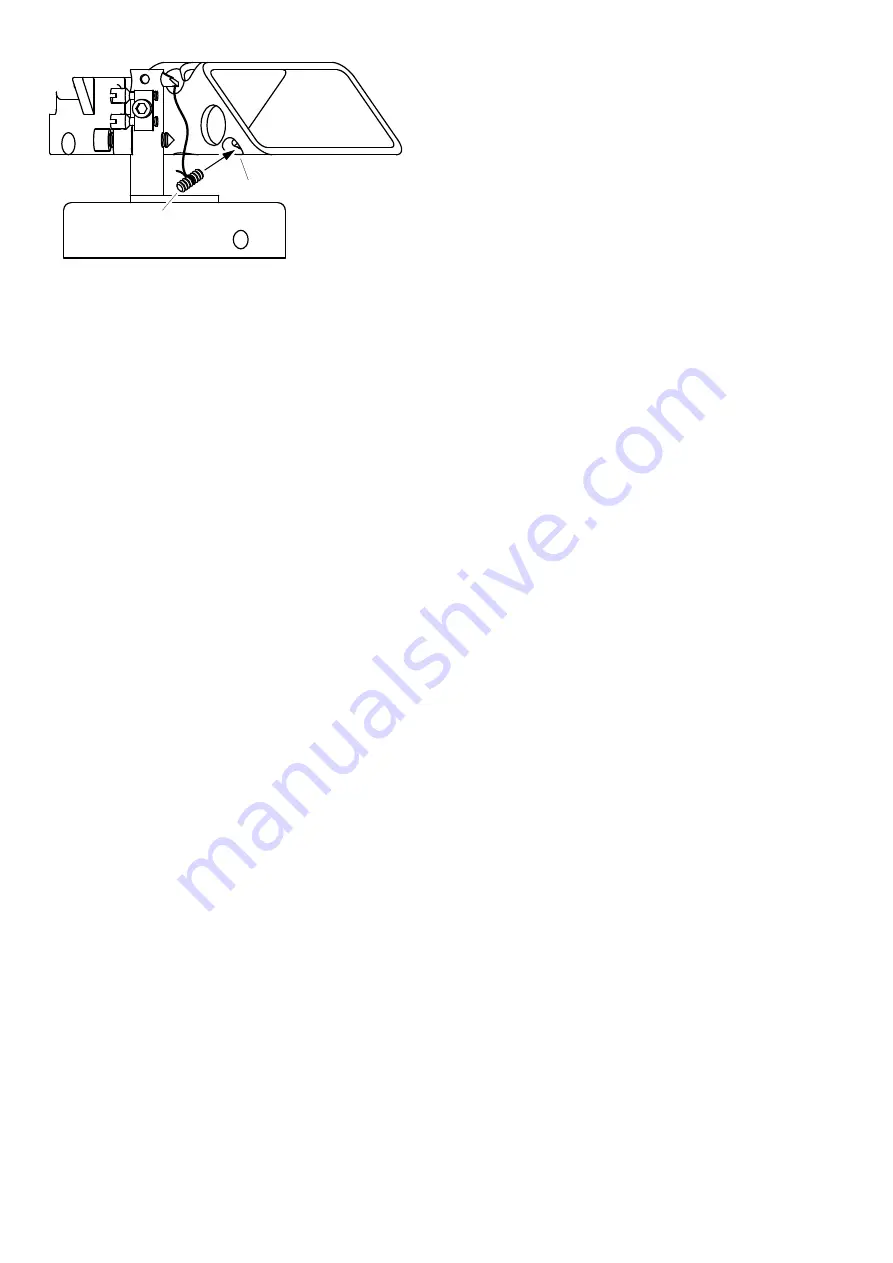

The right hoist toggle is attached only to the

right hoist. Allow the arm to rest gently

against the post, and tighten the spools so

that the arm is suspended level, and the

pivot point makes contact with the thrust

box exactly on the straight line between the

points where the hoists make contact with

the hoist holes.

Install Counterweight

The magnetic counterweight attaches

under the thrust box and can be slid

forwards and backwards to adjust the

downforce at the stylus end. Take care to

restrict movement of the arm while

adjusting the counterweight.

Use the supplied scale to set the required

downforce (see Set-up: Downforce). A 9g

inertia ('effective mass') adjuster is also

included, so be sure to set downforce after

placing the inertia adjuster on the arm in

the desired position.

Adjusting the inertia to suit the suspension

of your cartridge is an important way to

optimise the performance. Compliant

cartridges need a less inert arm, and stiffer

cartridges, a more inert. Satisfactory

right hoist

toggle

right hoist hole

8

results can be achieved by trial and error,

or by calculation. Blackbird has an effective

mass of 11g without the inertia adjuster.

Install Cartridge

Two-bolt cartridges can be installed in the

normal way. Placing a folded handkerchief

between the pivot point and thrust box

protects the pivot point. It is therefore not

necessary to dismount the arm for

cartridge installation. For a three-bolt

cartridge, remove the finger-lifter before

installing the cartridge and use the finger-

lifter hole to insert Allen key or screwdriver

when tightening the third cartridge bolt.

Remove String-lifter

You should be less likely to lose control of

the arm and less likely to damage your

records or cartridge with the string-lifter,

so it is recommended. A firm grip on the

string can be gained without applying

significant sideways or downwards forces

on the cartridge suspension.

However, if you wish to remove the string

finger-lifter and replace it with the

supplied rigid finger-lifter, use tweezers to

pull the knot at the base of the string out

from inside the arm tube, untie the knot,

and pull through.

Install Rigid Finger-lifter

To bolt the rigid finger-lifter in place, use a

sticky putty or a small loop of tape, sticky-

side-out, on the end of a screwdriver and

9