hold the nut in position inside the arm tube

to receive the countersunk M3 bolt. Once

the nut and bolt have engaged, insert a flat

screwdriver end between the nut and the

inner wall of the arm tube to lock the nut so

that you can tighten the bolt. Do not over-

tighten as this could damage the fragile

carbon-fibre arm tube.

Set Bias

The bias force (also known as ‘anti-skate’) is

adjusted in three ways.

First, the difference between applied bias at

the start and end of the record is adjusted

by shortening or lengthening the bias

pulley. Bias force varies more between the

rotor’s 11 o'clock and 12 o'clock positions

than between 9 o'clock and 10 o'clock.

Shortening the pulley will increase the

range of applied bias. To shorten it, pull at

the loose end when the arm is at rest.

Lengthen it by cuing the arm beyond the

last track of the record or further.

Always lengthen the pulley enough to

ensure that the bias rotor does not reach

the vertical position before the end of

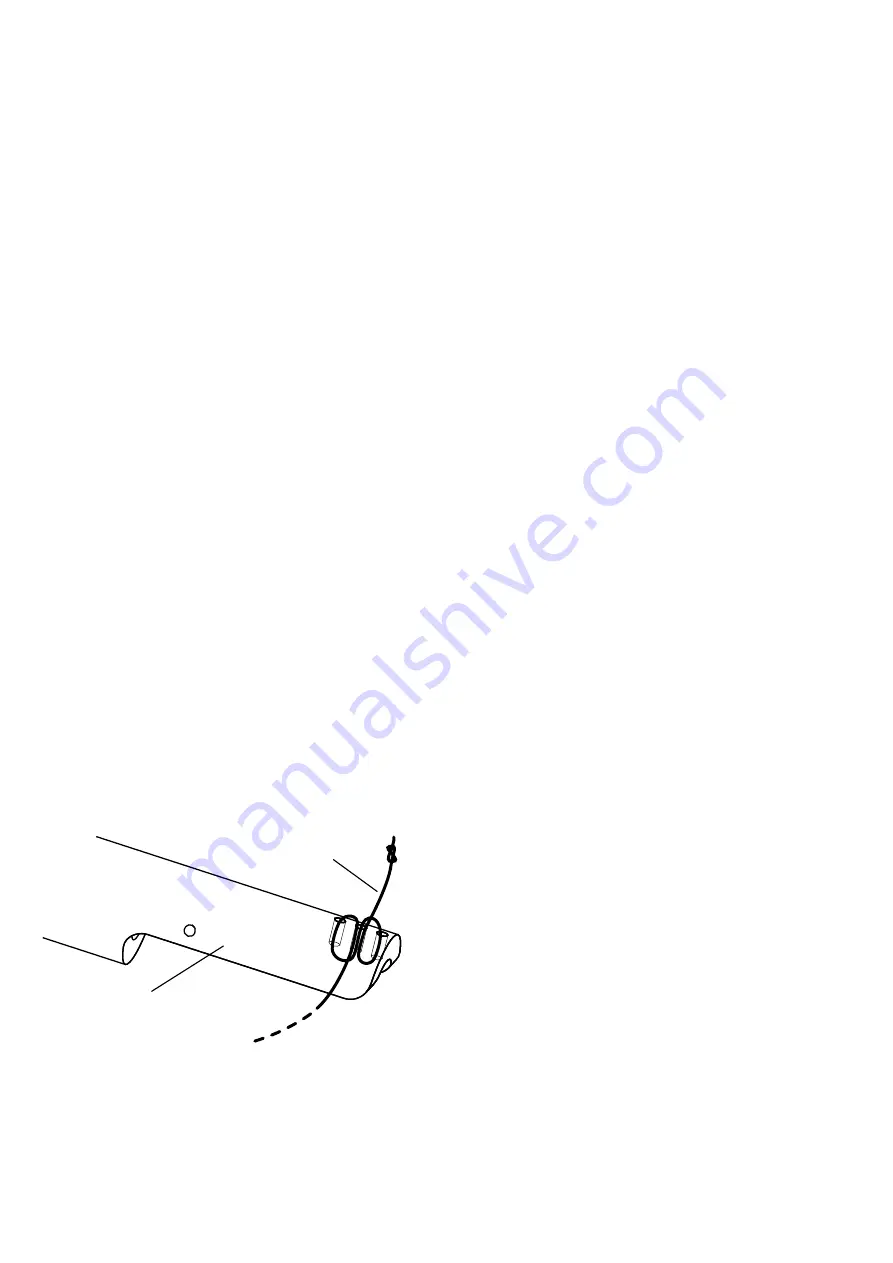

playback. A figure-of-eight pattern through

10

bias rotor

bias pulley

the bias rotor’s three holes, as illustrated, is

normally enough to grip the bias thread but

allow it to slip when forced.

The overall amount of bias is set by

tightening or loosing the grub screw inside

the rotor. The further the grub screw is

from the rotor’s axle, the more bias will be

applied. Do not tighten as far as the axle.

Finally, it is possible to adjust bias by

rotating the pillar in the base if you have

difficulty reaching correct bias by the

above methods.

Arm-Rest Magnets

In the rest position the thrust box attaches

to one, two, or three magnets in the bias rig,

which can be advanced or withdrawn using

a screwdriver to achieve a stable arm-rest

position. One magnet in the outer position

is often adequate, but adding a second or

third magnet in the other holes can help to

achieve a stable rest position.

Alignment

SUPATRAC’s ‘SUPATRACTOR’ is included to

make it easy to establish optimal spindle-

to-pivot distance, cartridge overhang and

null point alignment.

If it is difficult to set these distances

optimally on your turntable, you can

slightly adjust spindle-to-pivot distance by

withdrawing or extending both the pivot

bolt and hoist pipe in equal measure. If this

is done, the pillar and post will no longer be

11