3

4

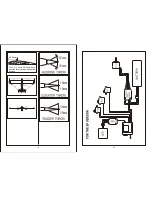

Place the servo tray on the center of

the main wing set. Use marker to

mark the location of the servo tray on

the main wing.

Use hobby knife to remove the

covering over the hole.

Use epoxy to secure the servo tray in

position.

Place the servo on the servo tray and

secure it in place with the screws

come with the servo.

Take two pieces of 330mm rods out

of the hardware bag. Use side cutter

to cut all the parts out of the plastic

parts tree. Screw a clevis onto the

threaded end of each rod. Thread the

aileron horns onto the aileron torque

rods in the wing until the rod is flush

with the aileron horn. Attach the

clevises onto their respective aileron

horns. Center the aileron servo and

using marker to place a mark on the

unthreaded end of the aileron

pushrods where they pass their

respective servo arm.

Using z-bend pliers, make a z-bend

at the marked location on each rod

and cut off the excess rod.

Use 2mm reamer to enlarge the hole

on the servo arm. Place a piece of

fuel tubing over the clevises.

This will provide extra insurance

against the clevises accidentally

coming open. Install the z-end into

the hole of the servo arm. Adjust the

aileron torque rod length by screwing

in or out until the aileron is exactly in

the neutral position when the servo is

centered and clevis is in the aileron

horn. Adjust both sides.

Find the pre-serving opening on both

sides of the fuselage for assembling

windows. Use hobby knife to remove

the covering over the openings.

Please reserve 6mm covering on the

edges of the openings.

O

Use iron (140 C) to trim the edges

and use hobby knife to remove the

excess covering.

Place the window set on the working

table and use curved scissors to

remove window from the window set.

Please reserve 6mm on the edges.

Spread UHU glue along the edges of