TABLE OF CONTENTS

Introduction

--------------------------------------------------------------------------------------------------------- 1

Specifications

------------------------------------------------------------------------------------------------------ 1

Features

-------------------------------------------------------------------------------------------------------------- 2

Environmental & Symbols & Safety

---------------------------------------------------------------------- 2-5

Contents Supplied

------------------------------------------------------------------------------------------------ 6

Assembly

---------------------------------------------------------------------------------------------------------- 6-8

Compactor Operation

---------------------------------------------------------------------------------------- 9-10

Maintenance

--------------------------------------------------------------------------------------------------- 10-13

Storage and Transporting

------------------------------------------------------------------------------------ 14

Trouble Shooting

------------------------------------------------------------------------------------------------ 15

Parts Breakdown

-------------------------------------------------------------------------------------------- 16-17

Introduction

Your new Vibratory Plate Compactor will more than satisfy your expectations. It has been

manufactured under' stringent quality standards to meet superior performance criteria. You will

find it easy and safe to operate, and with proper care, it will give you many years of dependable

service.

Carefully read through this entire operator's manual before using your new Log

Splitter. Take special care to heed the cautions and warnings.

1. The commitment to quality has been designed into details: reinforced self-cleaning base

plate, engine oil drain hose, closed V-belt guard, self-adjusting centrifugal clutch and folding

handle. A range of useful accessories enables use in all kinds of applications.

2. The Plate Compactor applies energy to the loose soil or other materials to increase its

density and load bearing capacity, mainly used for small repair and maintenance work. The

loose soil or particles are moved or rearranged in a particular manner close to each other to

avoid any trapped air or voids. It increases the load bearing capacity, decreases water

seepage, prevents soil settlement, reduces swelling, contraction of the soil and prevents

frost damage. It is ideal for compaction of granular soils, sands, gravel, crushed aggregate

and mixed soils.

These compactors are not intended to be used on cohesive soils such clay or

hard surfaces like concrete.

1. The Engine Manufacturer is responsible for all engine-related issues with regards to

performance, power rating, specifications, warranty and service. Please refer to the Engine

Manufacturer's owner/operator's manual, packed separately with your unit, for more

information.

Specifications

1

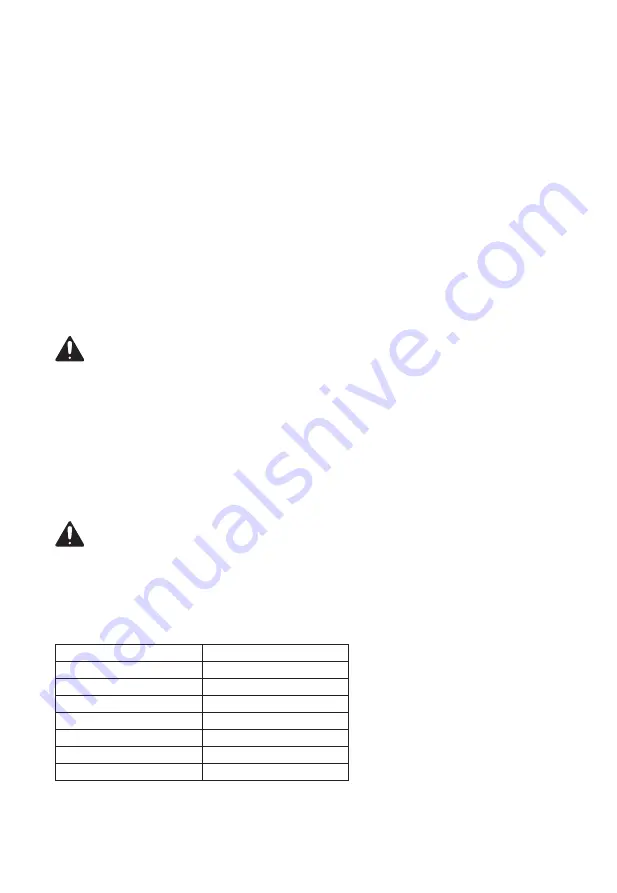

Item No.

Plate Size

Centrifugal Force

Exciter Speed

Compaction Depth

Travel Speed

Engine

Operation Weight

GUO039

20"×15"

4200lbf

5500vpm

12"

115FT/min

209cc

135lb

Summary of Contents for GUO039

Page 17: ...Parts Breakdown 16...

Page 19: ......