Great Circle USA

Support Line: 1-866-493-0524

help@greatcircleus.com

www.greatcircleus.com

8. Shut-off engine (see Stopping the Engine in the Operation section).

9. Hydraulic oil can be added appropriately when the cylinder thrust is insufficient.

For safety reasons, hydraulic oil, oil and fuel are not included in the package.

MAINTENANCE AND STORAGE

1. Always shut off the power source while repairing or adjusting the splitter except as recommended by the manufacturer.

2. Clean debris from the engine cylinder, cylinder head fins, recoil starter cover, and muffler areas. If the engine is equipped

with a spark arrestor muffler, clean and inspect it regularly (follow manufacturer’s service instructions). Replace, if damaged.

3. Never store the unit indoors with fuel in the tank. Fumes might reach an open flame spark. Allow the engine to cool before

storing in any enclosure.

4. Clear debris from movable parts, but only when the power source is shut off.

5. Check to be sure all nuts and bolts are tight to assure the equipment is in safe working condition prior to each usage, and

periodically during usage. Engine motor vibration may shake screws and bolts loose during operation.

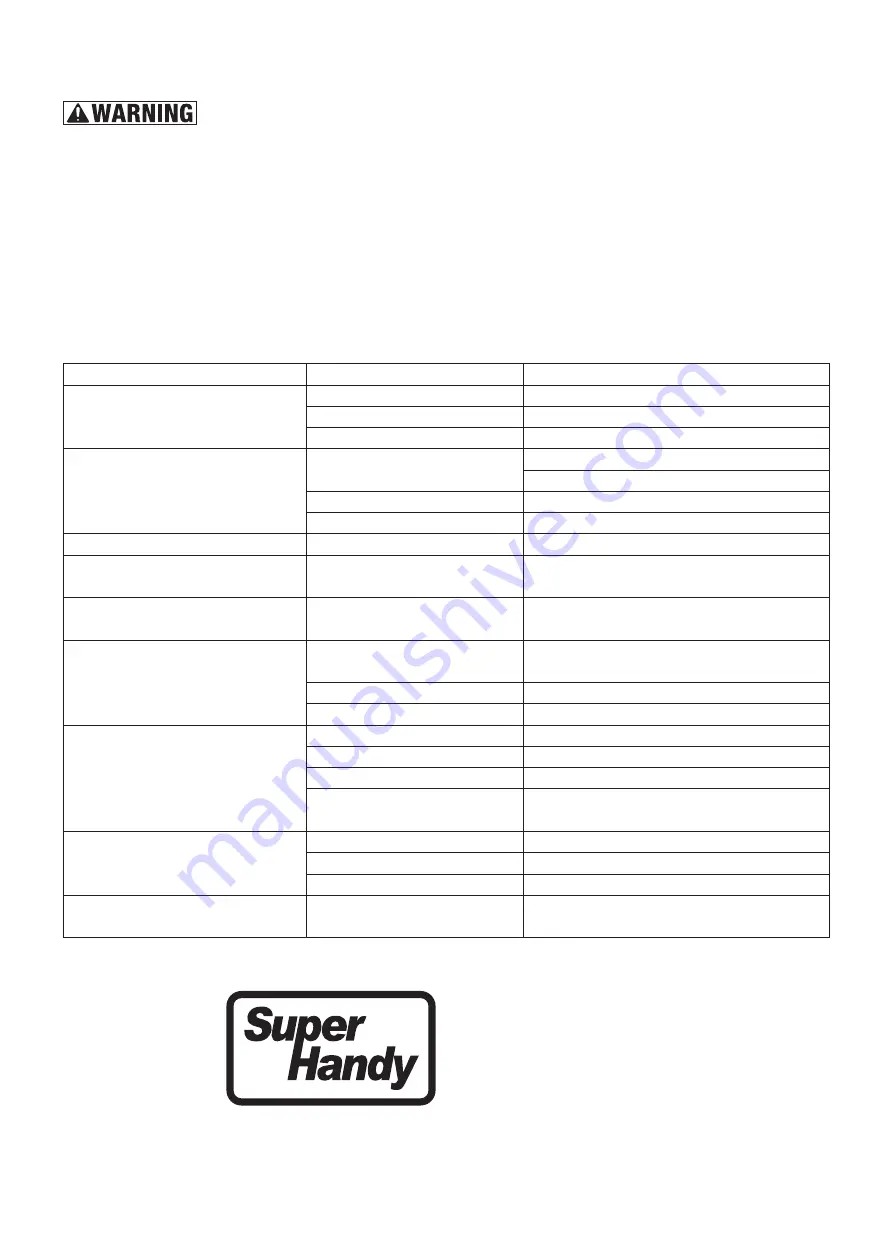

TROUBLE SHOOTING

Problem

Engine will not start.

Engine will not start.

Engine starts but runs roughly.

Engine shuts down during operation.

Engine cannot supply enough power

or overheating.

Wedge movement is slow or erratic.

Oil leak from cylinder.

Wedge will not extend or retract.

Excessive bouncing while towing.

Cause

No fuel.

Faulty spark plug.

Unit loaded during start up.

Low oil level.

Choke in the wrong position.

Spark plug wire loose.

Out of fuel.

Low oil level.

Insufficient ventilation.

Air in the hydraulic oil system.

Debris lodged in beam guides.

Low hydraulic oil.

Faulty cylinder rod seal.

Scored or bent cylinder rod.

Loose hydraulic fitting.

Faulty combination washer seal

on cylinder hydraulic fitting.

Faulty control valve.

Faulty hydraulic pump.

Low hydraulic oil.

Under-inflated tires.

Solution

Add fuel.

Replace spark plug.

Remove load from unit.

Fill crankcase to the proper level.

Place log splitter on a flat, level surface.

Adjust choke.

Attach wire to spark plug.

Fill fuel tank.

Fill crankcase to the proper level. Place log

splitter on a flat, level surface.

Check for air restriction. Move to a well

ventilated area.

Purge air by extending and retracting the wedge

several times until motion is smooth.

Clear debris from beam.

Check oil level and add as needed.

Contact Customer Service.

Contact Customer Service.

Tighten hydraulic fitting.

Contact Customer Service.

Contact Customer Service.

Contact Customer Service.

Check oil level and add as needed.

Inflate tires to proper pressure. Refer to tire

sidewall.

Size: 210x285mm

REV 04/23/21

157

克双铜

11

3.02.01.268