6-6

Publication: 0028607

LUBRICATION AND MAINTENANCE

6

Maintenance Items

NOTE

See Lubrication Recommendation Chart for servicing

the Camel™ truck. If a product is unavailable, contact

Super Products for a recommendation of alternate

products.

Boom

• Apply grease through the distribution fittings weekly.

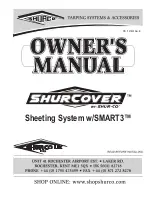

Figure 6-7

• Inspect boom bearing teeth for wear or cracking.

• The boom extension joint is a lifetime polymer slide.

No lubrication is necessary.

Debris Body

• Body Interior — Empty debris body daily and clean

interior using spray bar flushing system (if equipped)

or handgun. Clean tailgate sealing surface.

• Tailgate Seal — Clean the tailgate seal after each

discharge of debris with the use of the handgun.

Inspect the seal weekly for rips, tears, and proper

alignment with the body. Replace as necessary.

• Hydraulic Tailgate Latch Rollers — Clean the

tailgate latch rollers after each discharge. Lubricate

the rollers by hand with grease weekly and inspect

their condition. Repair or replace as necessary.

• Hydraulic Tailgate Latches — Clean any debris off

the latches daily. Lubricate the latch pivots and rollers

with grease weekly.

• Tailgate Lift Cylinder Pin — Inspect for wear.

Repair or replace as necessary.

• Float Ball — Clean the float ball daily or after each

load. Inspect the float ball weekly for dents and

proper sealing.

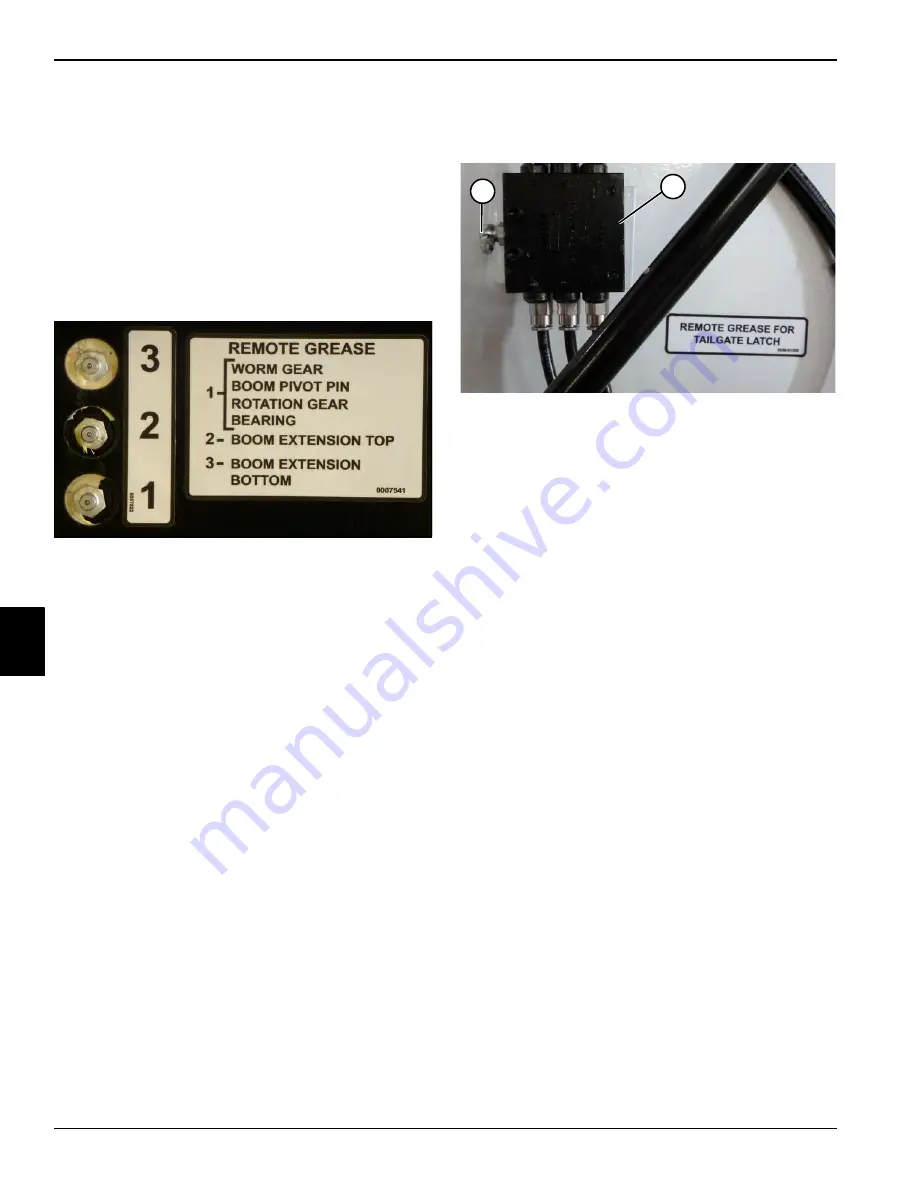

• Tailgate Hinge — Grease tailgate latch through the

grease zerk fitting (1) and distribution manifold (2)

weekly.

Figure 6-8

• Body Drain Valve and Hose — Inspect the valve for

proper sealing and the hose for leaks and wear

weekly. This applies to both rear and front drain (if

equipped).

• Debris Level Sensor (Option) — Make sure the

sensor is cleaned daily and after every debris dump.

Electrical System

• Lights — Make sure that all vehicle lights are

working properly.

• Pendant Plugs and Receptacles — Inspect the

pendant plugs and receptacles for proper contact

and alignment. Clean the terminals monthly and

lubricate them with dielectric grease.

NOTE

Avoid directly spraying electrical enclosures and

components with high-pressure water.

Boom Grease Distribution Fittings

Tailgate Grease Distribution Manifold

1

2

Summary of Contents for Camel 1200 (Dump Body)

Page 1: ......

Page 2: ......

Page 4: ......

Page 62: ...1 52 Publication 0028607 SAFETY 1...

Page 64: ...2 2 Publication 0028607 PRE OPERATION 2 Figure 2 1 Figure 2 2 1 3 2 5 6 4 7...

Page 106: ...4 18 Publication 0028607 SEWER CLEANING TYPICAL SEQUENCE 4...

Page 118: ...5 12 Publication 0028607 WATER RECYCLING SYSTEM 5...

Page 132: ...6 14 Publication 0028607 LUBRICATION AND MAINTENANCE 6...

Page 156: ...i vi Publication 0028607 IX...

Page 157: ......