5.

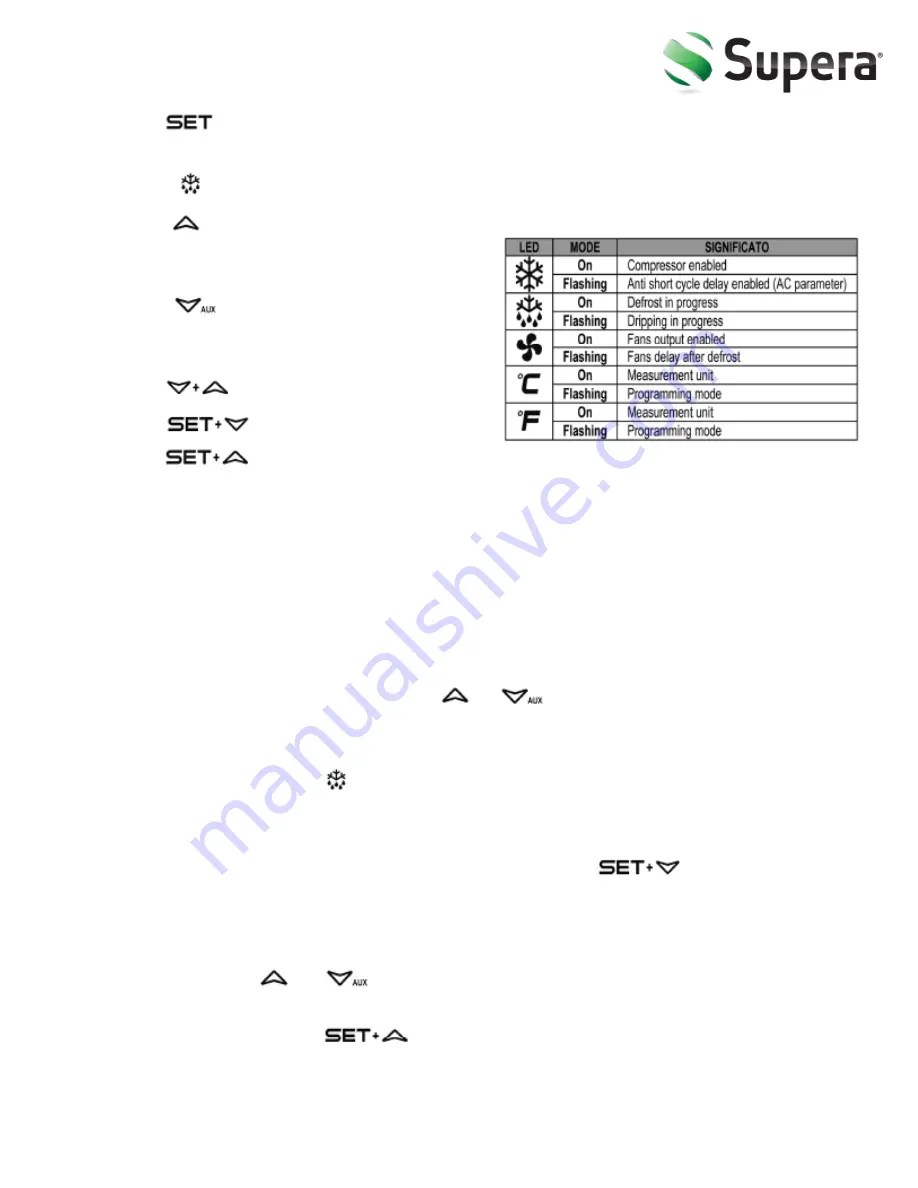

To display target set point, in programming mode it selects a parameter or

confirm an operation.

To start a manual defrost.

In programming mode it browse

the parameter codes of increased the

displayed value.

In programming mode it browses

the parameter codes or decreases the

displayed

value.

To lock or unlock the keyboard.

To enter in program mode.

To return to room temperature

display.

6. How to set the point:

•

Push and immediately release the SET key, the set point will be showed;

•

Push and immediately release the SET key or wait about 5 seconds to return to

normal visualization.

7. How to change the setpoint :

•

Push the SET key for more than 2 seconds to change the Set point value; The value

of the set point will be displayed and the "°C" or "°F" LED starts blinking;

•

To change the Set value push the

or

arrows.

•

To memorize the new set point value push the SET key again or wait 10 second

8. How to start a manual defrost:

•

Push the DEF

key for more than 2 seconds and a manual defrost will start.

9. How to change a parameter value:

•

To change the parameter's value operate as follows:

•

Enter the Programming mode by pressing the

keys for 3s

(“° C" or "°F" LED starts blinking).

•

Select the required parameter

•

Press the "SET" key to display its value

•

Use

or

to change its value

•

Press "SET" to store the new value and move to the following parameter

•

To exit: Press

or wait 15 seconds without pressing a key

9

V.1.0 | October 2014

©Supera