Superabrasive

Owner’s Manual –

LAVINA® 30L Pro /30L HV Pro

2/2014

24

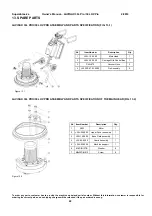

LAVINA® 30L PRO/30L HV PRO ASSEMBLY AND PARTS SPECIFICATION OF THE MAIN HEAD (FIG. 13.4)

TOP COVER

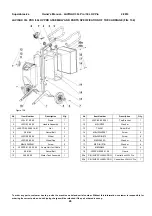

LAVINA® 30L PRO/30L HV PRO ASSEMBLY AND PARTS SPECIFICATION OF THE MAIN HEAD (FIG. 13.5)

BOTTOM COVER ASSEMBLY

To order any parts, customer has to provide the machine model and serial number. Without this information, customer is responsible for

ordering the correct part, and no shipping charges will be refunded if the part ordered is wrong.

№

Item Number

Description Qty.

1

L25SPS-04.00.00.01

Top Cover

1

2

L25SPS-04.01.00.00

Vacum Port

2

3

M5x16DIN84A

Screw

4

4

M5DIN125A

Washer

4

5

M5DIN127B

Washer

4

6

M5DIN934

Nut

4

№

Item Number

Description

Qty.

1 L25L.13.00.00 Deflection

Pulley

1

2 M8DIN127B

Washer 11

3 M8DIN934

Nut 11

4 L25L.10.00.15

Support 1

5 L25L.12.00.00 Tension

Support

1

6 L25L.10.00.16

Support 1

7 M6DIN7980

Washer 1

8 M6x30DIN933

Bolt

1

9 DIN6885A12X8X36

Key

1

10 PL2476/975L9

Belt

1

11 L25L.10.00.26

Insert

1

12 L25G.10.00.22 Leading

washer

1

13 L25NSPS-00.10.00.02 Front

Washer

1

14 L25NSPS.00.00.14

Bolt

1

15 L25L.10.00.14

Sector

1

16 L25L.10.00.07

Spindle 2

17 M10DIN934

Nut

2

18 L25L.10.00.12

Sector

1

19 L25L.10.00.13

Sector

1

20 L25L.10.00.08

Washer 1

21 L25L.10.00.11

Support 1

Figure 13.4

Figure 13.5