Superabrasive

Owner’s manual original language – Lavina

®

V20E

01/2020

10

5.SAFETY PRECAUTIONS

5.1 RECOMMENDED USE

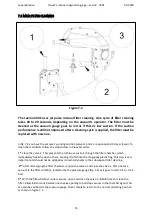

The LAVINA® V20E vacuum is designed and manufactured for use with concrete, terrazzo and

natural stone floors. It is recommended for use with LAVINA® machines. This vacuum is rated for

dry use only, and with a machine of appropriate size. For more information, please contact

Superabrasive.

5.2 PROHIBITED USE

The vacuum MUST NOT be used:

• For applications different from those stated in this manual;

• For collecting non-suitable materials (asbestos or other toxic materials);

• In environments which (1) Possess the risk of explosion, (2) Possess high concentration of powders

or oil substances in the air, (3) Possess the risk of fire, (4) Feature inclement conditions, (5) Possess

electromagnetic radiation;

5.3 PREPARATION FOR WORK

Ensure that:

• You have secured the working area, so that no person unfamiliar with operating the vacuum can

enter the area;

• The vacuum is not missing parts;

• The vacuum is in an upright, working position;

• All protection devices are working properly;

5.4 STOP FUNCTIONS

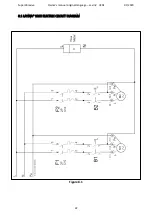

Functions for arresting of the machine include following:

• Three buttons to stop each motor separately;

5.5 SAFE USE

The LAVINA® V20E is designed to eliminate all potential risks associated with its use. However,

accidents may occur if unskilled or uninstructed workers fail to heed the list of potential risks below:

• Position Risks due to operator’s incorrect working position;

• Tangling Risks due to wearing inappropriate working clothes;

• Training Risks due to lack of operational training;

NOTE: Machine operators should follow the instructions in the manual at all times.

RESIDUAL RISKS During normal operating and maintenance cycles, the operator is exposed to some.

5.6 BEFORE YOU BEGIN

• The working area must be clear from any debris or objects.

• A first-time operator must always read the manual and heed all safety instructions.