WN-2500 / WN-3500 / WN-4500 / WN-6000

13

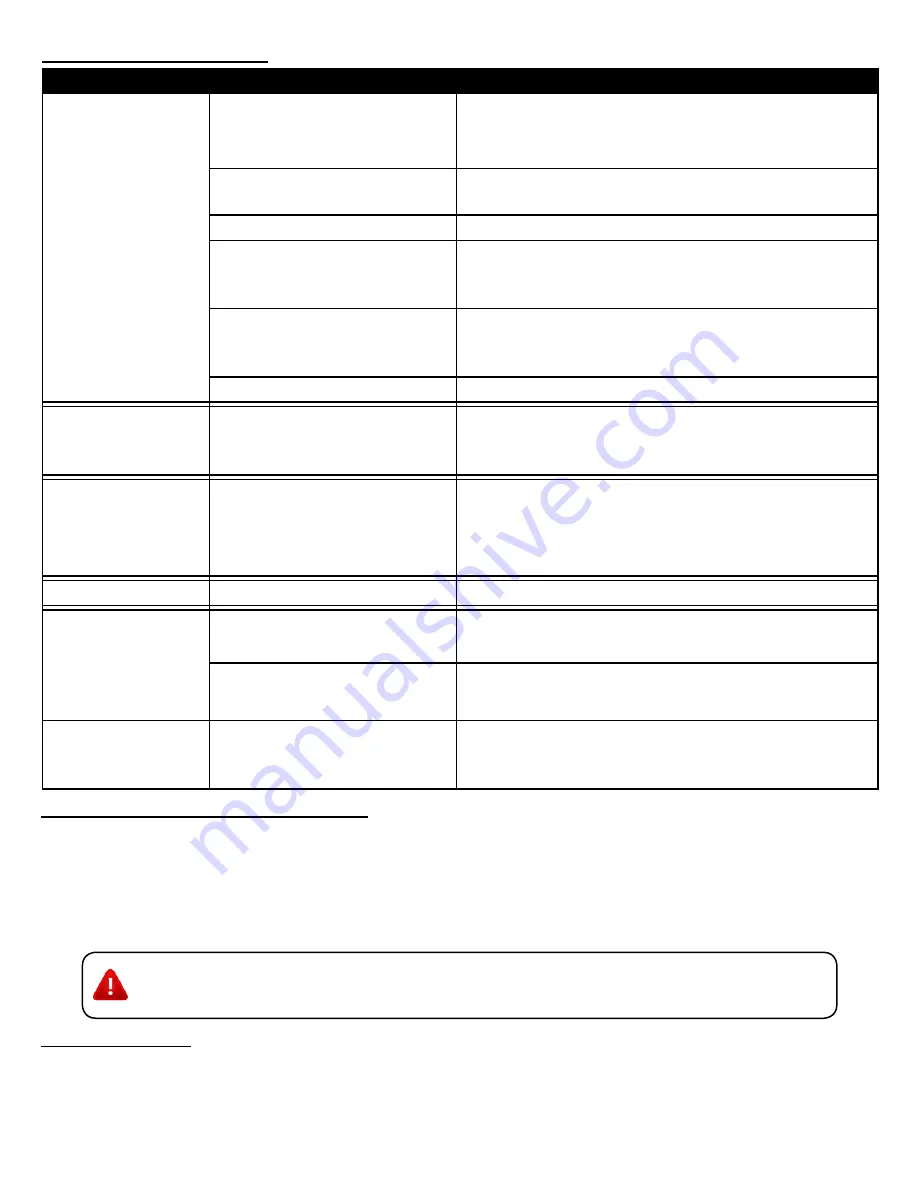

TROUBLE SHOOTING:

SYMPTOM

POSSIBLE CAUSE

SUGGESTED ACTION

Motor does not

turn on

Rocker Switch not connected

properly.

Insert Rocker Switch completely into Controls

Splitter Connector.

Connect ignition power source.

Loose battery cable

connections.

Tighten nuts on all cable connections.

Defective Rocker Switch.

Replace.

Defective Motor.

Check for voltage at armature port with Rocker

Switch pressed. If voltage is present, replace

Motor.

Water has entered Motor.

Allow water to drain and Winch to dry. Without a

load, operate Winch in short cycles until completely

dry.

Solenoid sticking.

Tap on Solenoid with handle end of screwdriver.

Motor runs but

Winch Drum does

not turn.

Free Spooling Clutch not

engaged.

Set Free Spooling Clutch to “IN” position. If

problem persist, contact SuperATV.

Motor runs slowly

or without normal

power.

Insufficient current or

voltage.

Battery is weak and may need charging. Always

operate Winch with vehicle running.

Corroded and/or loose battery cables should be

cleaned and tightened.

Motor overheating. Winch run time too long.

Periodically allow Winch to cool while operating.

Motor runs in one

direction only.

Defective Rocker Switch/

Remote Control.

Repair or replace Rocker Switch/Remote Control.

Loose battery cable

connections.

Corroded and/or loose battery or Motor cable

connections should be cleaned and tightened.

Motor runs

continuously on its

own.

Defective Solenoid, Wireless

Receiver, or Remote Control.

Unplug ignition power.

Remove negative battery cable from Solenoid.

SYNTHETIC ROPE MAINTENANCE:

-

Minimize abrasion:

Use movable Abrasion Sleeve whenever contact with rocks or other objects

occurs. Slide Abrasion Sleeve up and down Synthetic Rope as required. Abrasion will reduce

Synthetic Rope Life.

-

Keep clean:

Allowing dirt and debris to enter Synthetic Rope will lead to abrasion.

-

Avoid sharp bends:

A sharp bend will decrease Synthetic Ropes strength substantially under load

and may cause damage or failure.

MAINTENANCE:

- Check tightness of all mounting hardware and electrical connections periodically.

- Keep Winch clean. Remove all dirt and corrosion as required.

- Do not disassemble Mechanical Gear System. High temperature lithium grease has been applied at the

factory. No user maintenance is required.

WARNING:

If Synthetic Rope has become worn or is beginning to show signs of breaking,

replace immediately.

Replace with identical part number

. Refer to SuperATV

Synthetic Rope instruction when installing.