SuperiorFireplaces.us.com

127008-01_H

17

Figure 26 - Installing Grate Retainers

Figure 35 - Installing Fireplace Screen

Rating Plate

Hole for Screen Rod

Leading

Bricks

FIREBRICK WALL INSTALLATION

Continued

GROUTING INSTRUCTIONS

Material provided:

Bag of cement

Bag of sand

Material required:

Piping bag

Joints striker

Heavy duty mixing bucket

Sponge or Wet Cloth

1. Moisten brick surface with damp sponge or spray bottle just prior

to application. When bricks are wet, any excess grout mixture on

bricks will easily wipe off.

2. In a heavy duty mixing bucket, add equal parts cement and sand.

Add enough water and mix together well using a power drill with

mixing wand attachment to a yogurt like consistency. Not adding

enough water can lead to grout falling out after burning.

3. The overall length of piping bag should be about 16". If the bag is

longer than 16", cut it down to size by removing end with larger

opening. This will make the bag easier to handle.

4. Put grout mixture into piping bag making sure the smaller opening

is downward and over a moist towel to avoid spilling. Place a wet

towel over the bucket making sure it is directly on the surface of

grout mixture. This will keep the mixture moist and it will not dry

out before use.

5. Grout all joints where two firebrick walls come together.

6. Using a trowel, remove excess grout mixture by moving trowel in

the direction of the joint. Grout mixture in the joint should now be

flush with brick surface. If not enough grout is applied into each

space, grout may fall out after burning.

7. Using a joint striker, smooth out grout line.

Allow 72 hours before operating fireplace.

INSTALLING SCREEN

1. Slide round end of screen rod into rings at top of screen. Attach one

push-on nut to end of rod before attaching last ring of screen.

2. Insert the round end screen rod into hole on the left and right side

of smoke shelf (Figure 35).

3. Mount flat end of screen rod with #10 x 5/8" to center of smoke

shelf.

4. Install other screen rod in same manner.

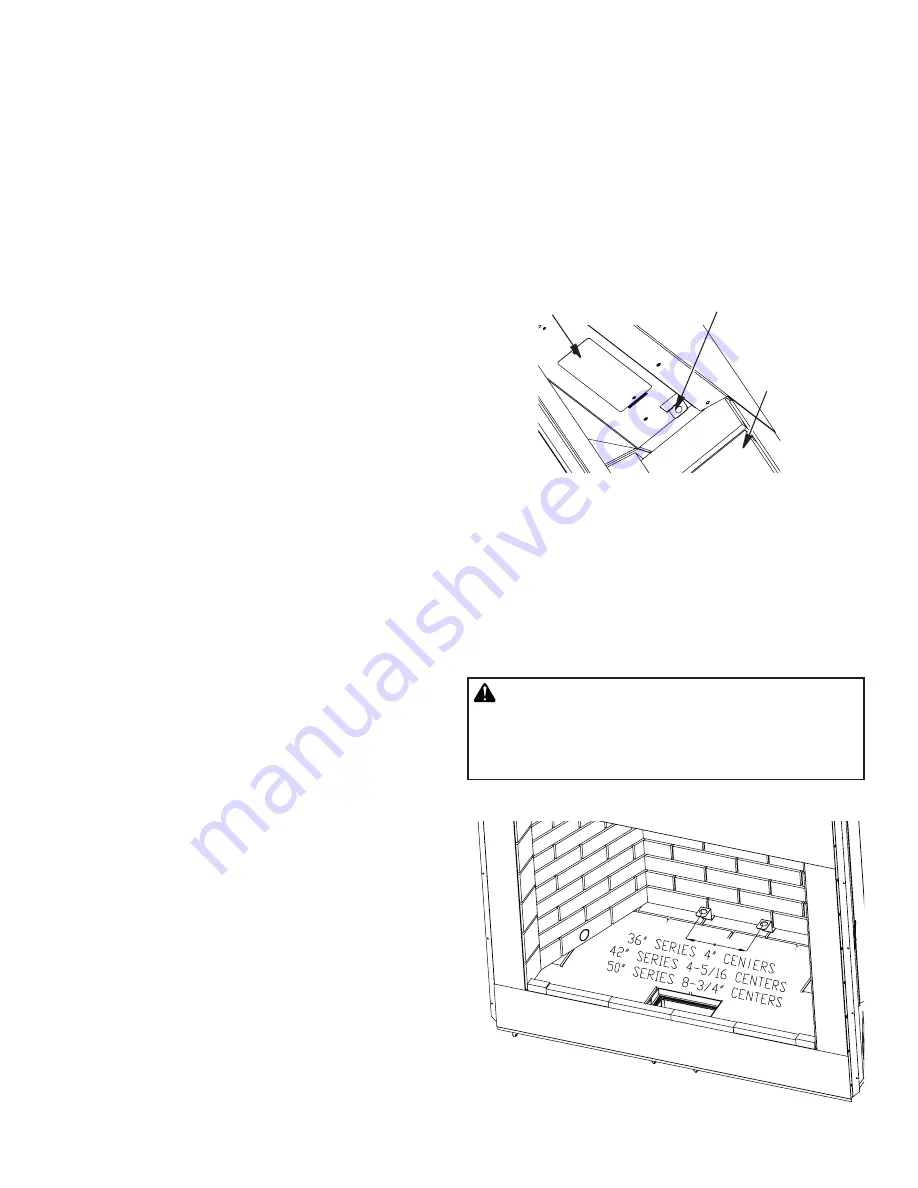

INSTALLING GRATE RETAINERS

1. Place the provided grate retainers on the hearth as shown in Figure

36. The back of the retainer will be flush with the rear firebrick wall.

Mark the center of the hole on the hearth with a marker.

2. Drill two holes in the hearth in the marked locations using a masonry

3/16" drill bit.

3. Secure grate retainer with masonry screws provided.

WARNING: Risk of fire! Replace grate with an IN-

NOVATIVE HEARTH PRODUCTS grate only (see Parts,

pages 22 and 23). This grate has been designed to

keep the operation of your fireplace safe and efficient.