Installation & Operation Manual

O-360 and IO-360 Series Engines

© March 2004 Superior Air Parts Inc. Chapter 1 • Engine Description

13

5. FEATURES AND OPERATING

MECHANISMS

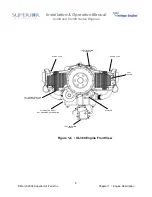

Crankshaft - The crankshaft is made from

aerospace grade SAE 4340 Vacuum-Arc-Remelt

(V.A.R.) steel per AMS 6414. All bearing journal

surfaces are nitrided.

Connecting Rods - The connecting rods are

made from aerospace grade SAE 8740 forgings

per AMS 6325. They have replaceable bearing

inserts in the crankshaft ends and bronze

bushings in the piston ends. The bearing caps

on the crankshaft ends are retained by two bolts

with self locking nuts per cap. Caps are tongue

and groove type for improved alignment and

rigidity.

Camshaft - Valve Operating Mechanism - The

camshaft is located above and parallel to the

crankshaft. The camshaft actuates hydraulic

lifters that operate the valves through push rods

and valve rockers.

Crankcase - The crankcase is made from

aerospace grade AA C355-T71 stabilized

structural aluminum alloy per AMS 4214. The

assembly consists of two reinforced aluminum

alloy castings fastened together by means of

studs, bolts, and nuts. The main bearing bores

are machined for use with precision type main

bearing inserts.

Accessory Housing - The accessory housing is

made from an aluminum casting and is fastened

to the rear of the crankcase and the top rear of

the sump.

Oil Sump - The sump incorporates an oil drain

plug, oil suction screen, mounting pad for

carburetor or fuel injector, the intake riser, and

intake pipe connections.

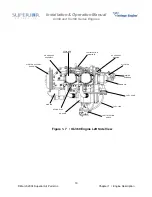

Cylinders - Millennium

®

Cylinders are used

exclusively. These air-cooled cylinders are

manufactured by screwing and shrinking the two

major parts, head and barrel, together. The

heads are made from AMS 4220 aluminum alloy

casting material. All barrels are made from

forgings produced to AMS 6382 forging

specifications. They are internally choked and

honed to allow optimal operating conditions for

the rings and pistons at operating temperatures.

Pistons - The pistons are made from an

aluminum alloy. The piston pin is a full floating

type with a plug located in each end of the pin.

The piston is a 3-ring type with 2 compression

rings and 1 oil control ring.

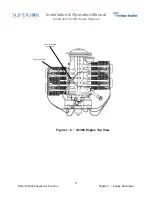

Cooling System – Superior Vantage Engines

are designed to be air-cooled. Baffles are

provided to build up air pressure and force the

air between the cylinder fins. The air is

exhausted to the atmosphere through the rear of

the cowling.

Induction System - The distribution of the air to

each cylinder is through the center zone of the

induction system. This is integral with the oil

sump.

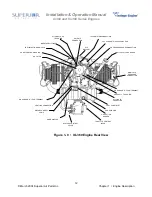

Fuel Systems

Carbureted - Superior Air Parts O-360 engines

are equipped with a float type carburetor The

MA-4-5 carburetors are of the single barrel float

type equipped with a manual mixture control and

an idle cut-off.

Fuel Injected - IO-360 series engines are

equipped with a direct cylinder injected RSA-5

fuel injector. The fuel injection system

schedules fuel flow in proportion to airflow. Fuel

vaporization takes place at the intake ports. The

RSA fuel injection system is based on the

principle of measuring airflow and using the air

pressure in a stem type regulator, converting the

air pressure into a fuel pressure. The fuel

pressure (fuel pressure differential), when

applied across the fuel metering section (jetting

system), makes fuel flow proportional to airflow.

Lubrication System - The full pressure wet

sump lubrication system is supplied by a gear

type pump. It is contained within the accessory

housing.

Priming System - A manual primer system is

provided on all engines using a carburetor. Fuel

injected engines do not require a manual

priming system, relying instead on the fuel

injectors for priming.

Ignition System - Dual ignition is furnished by

two Unison magnetos with two spark plugs per

cylinder. Each magneto is equipped with

impulse coupling for improved starting.