Installation & Operation Manual

O-360 and IO-360 Series Engines

12 Chapter 3 • Aircraft / Engine

© March 2004 Superior Air Parts Inc. Integration Considerations

6. LUBRICATION SYSTEM

The engine lubrication system is responsible for

the reduction in friction between components,

removal of combustion by-products and other

contaminants, and the removal of heat from

internal engine components. A continuous

supply of clean, cooled oil of the proper grade

and specification is essential to this process.

Failure to do so can result in a wide variety of

problems ranging from increased wear to engine

stoppage.

A. Lubricating Oil Requirements

Superior recommends the use of high quality

100% mineral oil during the break-in period.

After engine break-in, high quality ashless

dispersant engine oil per MIL-L-22851 or SAE J-

1899 should be used in Superior Vantage

Engines. Ashless dispersant oils are used to

prevent the formation of sludge, aid in the

neutralization of corrosive acids and prevent ash

deposits on cylinder walls that can become hot

spots and sources for pre-ignition. The grade or

viscosity of oil should be chosen based upon the

climate where the engine will be operated as

shown in Table 8-1.

Superior Vantage Engines are provided with a

suction screen filter, sometimes referred to as a

“finger filter” to prevent large contaminants from

being drawn into the pressurized portion of the

oil system. In addition, Superior Vantage

Engines are provided with a full-flow oil filter to

maintain contaminant free oil and promote long

engine life. Superior recommends changing the

full-flow oil filter, inspecting / cleaning the suction

screen filter and changing the oil in accordance

with published maintenance schedules.

In addition to clean oil of the proper viscosity, it

is important to ensure that the oil is free of

aeration and foam in the pressurized portion of

the oil system. This can become an issue at

high altitudes as the vapor pressure of the oil

exceeds the ambient pressure. Severe aeration

within the anticipated flight altitudes of a

Superior Vantage normally aspirated engine, but

must be verified through flight testing.

B. Lubricating System Components

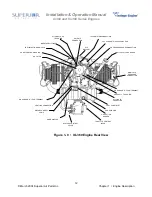

The lubricating system of Superior Vantage

Engines is composed in general of an oil sump

or reservoir, an oil cooler circuit, an internal

pressurized circuit and for installations with

constant speed propellers a propeller governor

circuit. A schematic of the lubricating system is

provided in Figure 3-1.

(1.) Oil Sump

Superior Vantage Engines utilize a “wet sump”

design. That is, the engine oil sump is the

primary reservoir for engine oil as opposed to a

remote reservoir as is done in many aerobatic

installations. However, provisions exist to attach

an aerobatic oil system to the Superior Vantage

Engine if desired. For more information

regarding aerobatic installations contact

Superior Air Parts.

The maximum capacity of the oil sump is 8 U.S.

quarts. Oil quantities in excess of this amount

can cause loss of engine efficiency due to

“splashing” and fluid drag of internal

components through the oil and also “pumping”

of the oil out the crankcase breather fitting.

Minimum oil capacity is governed by the ability

of the oil pump to draw full oil (i.e. no entrained

air) from the sump in various flight attitudes.

(2.) Oil Pump and Pressure Control Valve

Superior Vantage Engines employ a high flow,

positive displacement gear pump to provide oil

throughout the engine. The pump is capable of

producing oil flow and pressure values much

higher than those required by the engine as a

safety measure to ensure that the necessary oil

is always available to the engine. Because of

this, a pressure control valve is used to govern

the maximum oil pressure in the system. Oil

pressures that are too high will promote external

leaks that would not otherwise occur.

The oil pressure control valve is adjustable so

that the operator may ensure that the oil

pressure is within specified limits. If oil pressure

under normal operating conditions always

exceeds the maximum or minimum specified

limits as defined in Table 5 of the Model