Installation & Operation Manual

O-360 and IO-360 Series Engines

4

© March 2004 Superior Air Parts Inc. Chapter 7 • Abnormal Operating Procedures

7. LOW OIL PRESSURE ON ENGINE GAGE

8. HIGH OIL TEMPERATURE

9. EXCESSIVE OIL CONSUMPTION

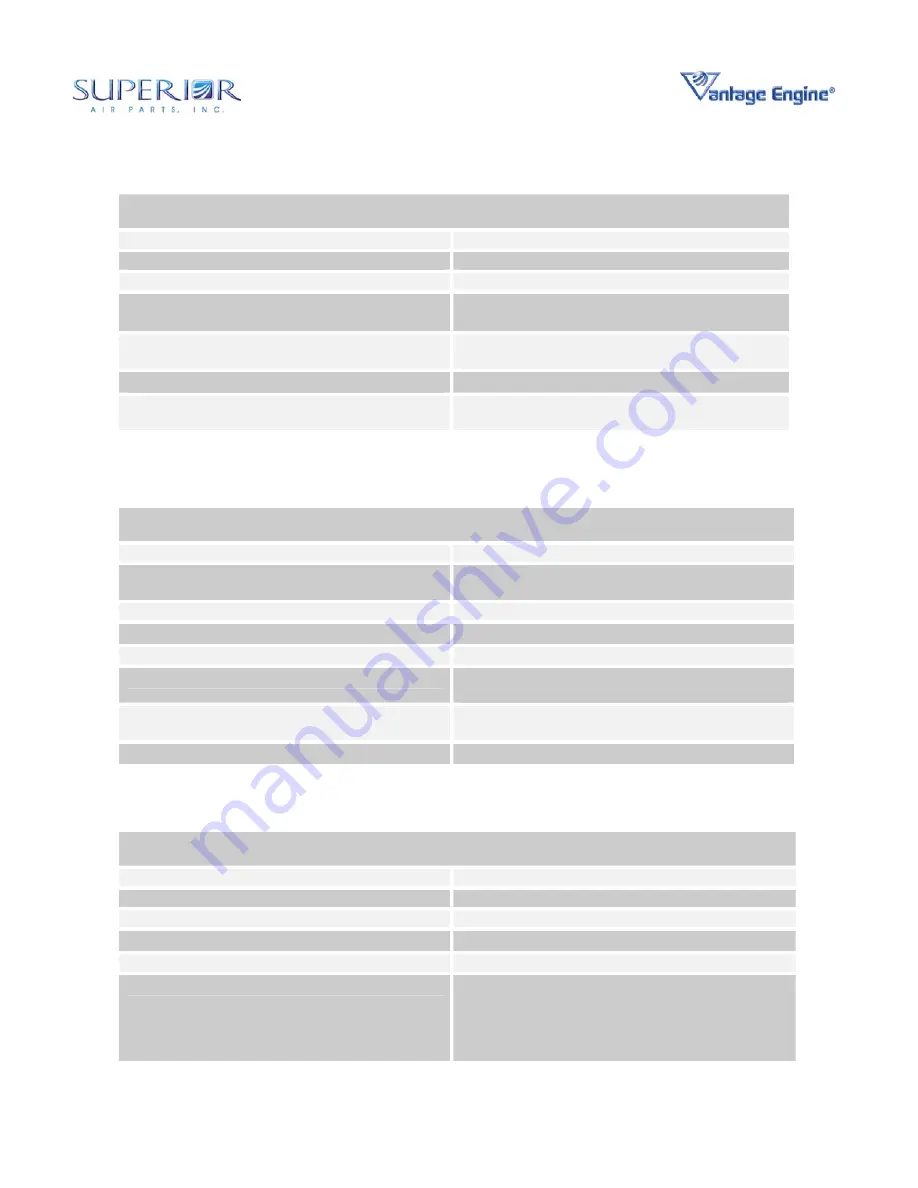

Table 7-7 • Low Oil Pressure On Engine Gage

Probable Cause

Correction

Lack of oil

Add to proper level.

Air lock or dirty relief valve

Clean relief valve.

Leak in line

Inspect gasket between accessory housing and

crankcase.

High oil temperature

See "High Oil Temperature" in "Trouble"

column.

Defective pressure gage.

Replace defective gage.

Stoppage in oil pump intake passage

Check line for obstruction. Clean suction

strainer.

Table 7-8 • High Oil Temperature

Probable Cause

Correction

Insufficient air cooling

Check air inlet and outlet for deformation or

obstruction.

Insufficient oil supply

Fill to proper level with specified oil.

Low grade of oil

Replace with oil conforming to specifications.

Clogged oil lines or strainers

Remove and clean oil strainers.

Excessive blow-by

Check condition of engine rings. Replace if worn

or damaged.

Failing or failed bearing

Examine sump for metal particles. If found,

engine overhaul may be required.

Defective temperature gage

Replace gage.

Table 7-9 • Excessive Oil Consumption

Probable Cause

Correction

Low grade of oil

Fill tank with oil of proper weight and grade.

Failing or failed bearings

Check sump oil for metal particles.

Worn piston rings

Install new rings.

Incorrect installation of piston rings

Install new rings.

Failure of rings to seat on new cylinders

Use mineral base oil. Climb to cruise altitude at

full power and operate at 75% cruise power

setting until oil consumption stabilizes. See

Break-In Procedures, Special Procedures

Section Chapter 5.