SUPERIOR

®

E

n

g

li

s

h

11

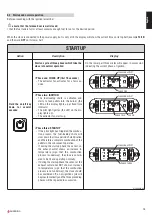

1.10 Connecting to a conventional chimney - Fig. 21-22

If you wish to use an existing chimney it is strongly recommended that

you have it checked by a professional chimney-sweep to ensure that it

is completely airtight. The reason for this is that the smoke, because it

is slightly pressurised, can infiltrate any cracks in the system and esca-

pe into living spaces. If upon inspection you find that the chimney is not

completely sound, it is recommended that you insert piping made of

new material. If the existing chimney is wide enough we recommend a

pipe with a maximum diameter of 150mm. It is also recommended that

you insulate the chimney flue (Fig. 21-22).

For connection to the chimney the use of Piazzetta’s own pipes and

bends is recommended - the stove’s outlet is the right size to connect

to these.

Other types of pipe can be used, provided that they are suitable or that

the compatibility of the connecting sleeve can be verified. Bear in mind

also that pipes and bends must be constructed according to existing

regulations. In such cases however Gruppo Piazzetta S.p.A guarantees

the proper functioning of the stove only where its own equipment has

been employed in accordance with its own instructions.

The connection to the flue system must respect the

40cm minimum

safety distance

from objects which are sensitive to heat and from

inflammable materials (wooden veneers, beams or ceilings etc). (See

figures 17-18)

- If the connector has to pass through partitions or walls constructed

from inflammable or heat-sensitive materials, or through weight-bea-

ring walls, you must introduce:

an insulated barrier equal to or greater than 10cm around the con-

nector using a mineral-based insulating material (rock wool, ceramic

fibre) with a nominal density greater than 80kg/m

3

- If the connector has to pass through partitions or walls construc-

ted from heat-resistant materials, you must introduce:

an insulated barrier equal to or greater than 5cm around the con-

nector using a mineral-based insulating material (rock wool, cera-

mic fibre) with a nominal density greater than 80kg/m

3

.

- Check that the connection to the flue system has been carried out so

as to guarantee that smoke will not leak from it under the equipmen-

t’s pressurised operating conditions.

- Check that the pipe does enter too far into the flue creating a narro-

wing of the exhaust passage. Figure 22-23

Ensure that all installation work is carried out to professio-

nal standards.

COMIGNOLO

RACCORDO A T

CON CANNA FUMARIA

NON INTEGRA

INSERIMENTO DI

UN TUBO

SPORTELLI PER

ISPEZIONE

ISOLANTE

Max ø150 mm

ø 80 mm

DT2030339-00

Fig. 21

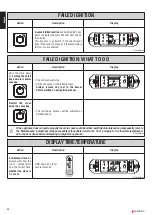

FLANGIA DI CHIUSURA

FLANGIA DI CHIUSURA ERMETICA

IN ACCIAIO INOX O ALLUMINATO

PRESA D'ARIA ESTERNA

CON GRIGLIA NON RICHIUDIBILE

DT2030340-00

Fig. 22

Insulating material

Tee

Chimney stack

Pipe insertion

With damaged flue

Inspection

windows

Closing flange

Sealing flange in stainless

steel or aluminium

Fresh air intake with

non-closable grille