7

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

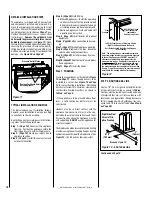

The vent / air intake termination clearances

above the high side of an angled roof is as

shown in the following chart:

12

X

Roof Pitch is X/12

2 FT

MIN.

2 FT MIN.

Lowest

Discharge

Opening

H*

*H = MINIMUM HEIGHT FROM ROOF TO

LOWEST DISCHARGE OPENING OF VENT

TERMINATION HEIGHTS FOR VENTS ABOVE

FLAT OR SLOPED ROOFS

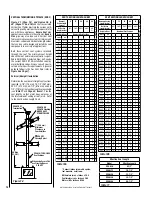

Horizontal Overhang

Vertical

Wall

Vent

Termination

Storm Collar

Concentric

Vent Pipe

Flashing

1 inch (25.4 mm) Minimum

Clearance to Combustibles

Figure 5

Vertical Vent Termination Clearances

VENT TERMINATION CLEARANCES

These instructions should be used as a guide-

line and do not supersede local codes in any

way. Install vent according to local codes,

these instructions, the current National Fuel

Gas Code (ANSI-Z223.1) in the USA or the

current standards of CAN/CGA-B149.1 and

-B149.2 in Canada.

Terminate multiple vent terminations according to

the installation codes listed above.

Terminate single vent caps relative to building

components according to

Figure 5

.

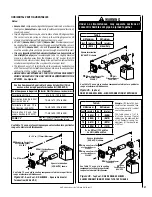

Horizontal Vent Termination Clearances

The horizontal vent termination must have a minimum of 3" (76 mm) clearance to any overhead

combustible projection of 2 1/2" (64 mm) or less.

For projections exceeding 2 1/2" (64 mm), see

Figure 6

. All horizontal terminations may be located as close as 6" (152mm) to any combustible

exterior sidewall. This distance may be decreased to 2" (51mm) if the SV4.5HT-2 or SF4.5HT-2

termination is used and the exterior sidewall is

non-combustible only

. For additional vent location

restrictions refer to

Figure 7 on Page 8

.

Termination Heights For Vents

Above Flat Or Sloped Roofs

Ref. NFPA 54 / ANSI Z223.1, 7.6

Roof Pitch

* Feet

* Meters

Flat to 6/12

1.0

0.3

6/12 to 7/12

1.25

0.38

7/12 to 8/12

1.5

0.46

8/12 to 9/12

2.0

0.61

9/12 to 10/12

2.5

0.76

10/12 to 11/12

3.25

0.99

11/12 to 12/12

4.0

1.22

12/12 to 14/12

5.0

1.52

14/12 to 16/12

6.0

1.83

16/12 to 18/12

7.0

2.13

18/12 to 20/12

7.5

2.29

20/12 to 21/12

8.0

2.44

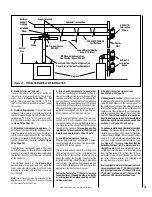

Side Elevation View

Note - See Figure 33 on Page 20 for the exterior wall recess allowances of the square horizontal termination.

Figure 6

3"

(76 mm)

12"

(305 mm)

Termination Kit

Combustible Projection

greater than

inches in length

Combustible Projection

2-1/2 inches or less in length

18"

(457 mm)

Ventilated

Soffit

Unventilated

Soffit

Horizontal Vent Termination Clearances

2-1/2

Termination Kit

All horizontal terminations

may be located as close

as 6” (152mm) to any

(non-combustible and

combustible) exterior

sidewall. This distance

may be decreased to

2” (51mm) for non-

combustible exterior

sidewalls only, if the

SV4.5HT-2 or SF4.5HT-2

termination

is used.