12

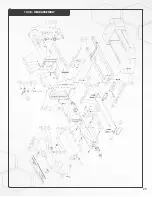

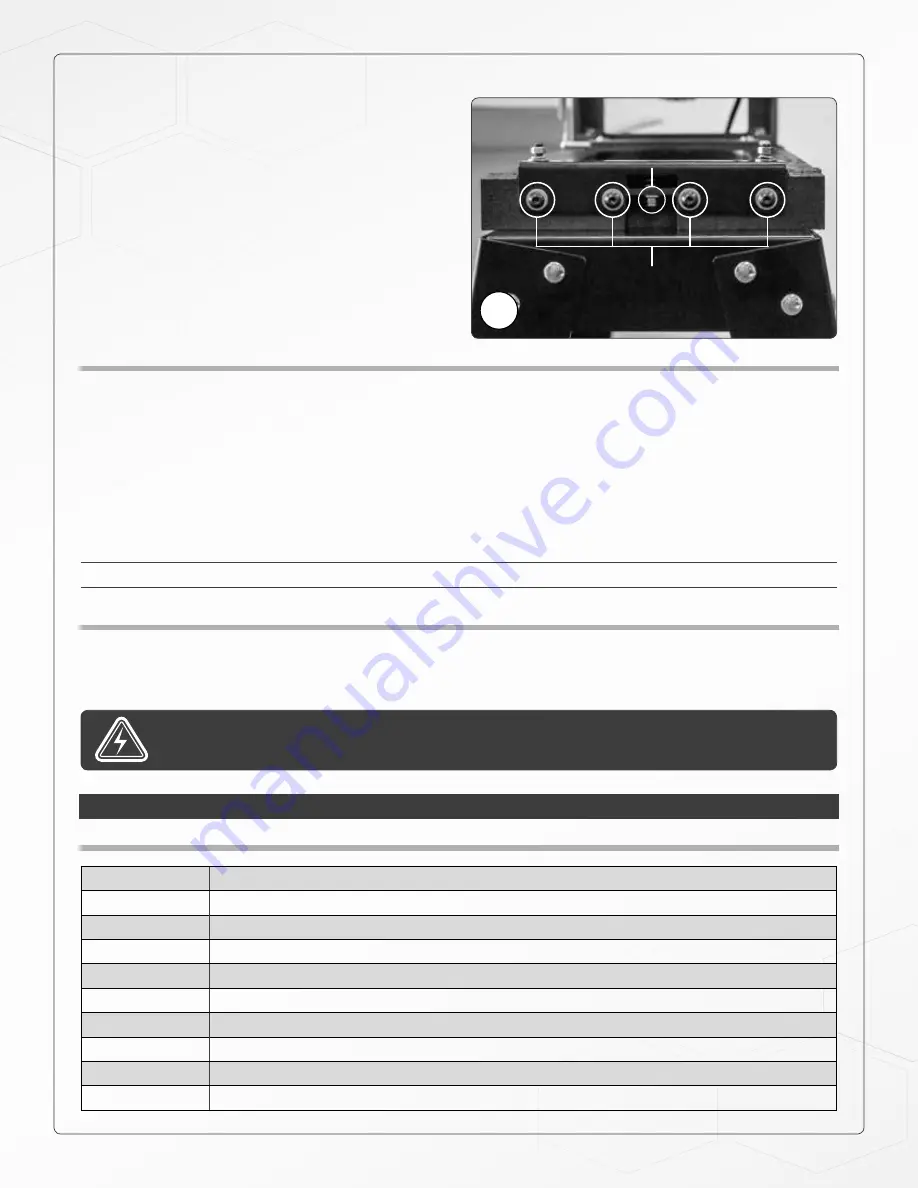

If the drum is not parallel, loosen the 4 socket head

screws

A

(these screws are along the outboard (left)

side of the conveyor belt) and raise or lower the

conveyor with the adjustment nut

B

to achieve parallel

alignment. Then tighten the four socket head screws.

To achieve parallel alignment on the inboard (right)

side of the machine, repeat steps 3 and 4, then adjust

the alignment if needed by loosening the 4 socket

head screws located along the outboard (left) side of

the conveyor and turning the height adjustment nut of

the conveyor.

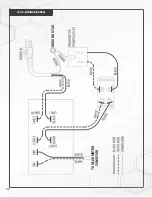

CONNECTING DUST COLLECTORS

Dust collection is necessary for the SuperMax Tools 19-38 drum sander. The sander comes equipped with a 4”

diameter dust exhaust port at the top of the cover. Check to make sure that the minimum dust requirements are

sufficient.

To attach to your collection system, install 4” hose from your collector. The minimum recommended dust col-

lector capacities is 600 cfm. For best results, follow the recommendations of the manufacturer of your dust

collection equipment.

When connecting dust collectors straight pipe is preferred because it is the least restrictive for airflow. If straight

pipe is not possible Y’s and elbows are preferred because they are less restrictive to airflow than T’s.

NOTE: Some applications will require more dust collection than the recommended minimum.

POWER AND ELECTRICAL SAFETY

The SuperMax Tools 19-38 drum sander requires 110 V, single-phase 20 A service. After the dust collection sys-

tem is in place and the drum alignment is checked your machine should be ready to be powered up and operated.

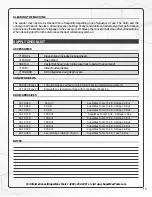

ABRASIVE SELECTION GUIDE

GRIT COMMON APPLICATION

24 Grit

Abrasive planing, surfacing rough-sawn boards, maximum stock or glue removal

36 Grit

Abrasive planing, surfacing rough-sawn boards, maximum stock or glue removal

50 Grit

Surfacing and dimensioning boards, trueing warped boards

60 Grit

Surfacing and dimensioning boards, trueing warped boards

80 Grit

Light dimensioning, removal of planer ripples

100 Grit

Light surfacing, removal of planer ripples

120 Grit

Light surfacing, minimal stock removal

150 Grit

Finish sanding, minimal stock removal

180 Grit

Finish sanding only, not for stock removal

220 Grit

Finish sanding only, not for stock removal

SAFETY NOTE: DO NOT REWIRE THE SUPERMAX TOOLS 19-38 DRUM SANDER TO 220 VOLT. ALWAYS

DISCONNECT ELECTRICAL POWER BEFORE DOING ANY SERVICING OR ADJUSTING OF THE MACHINE.

A

B

5