14

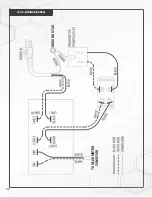

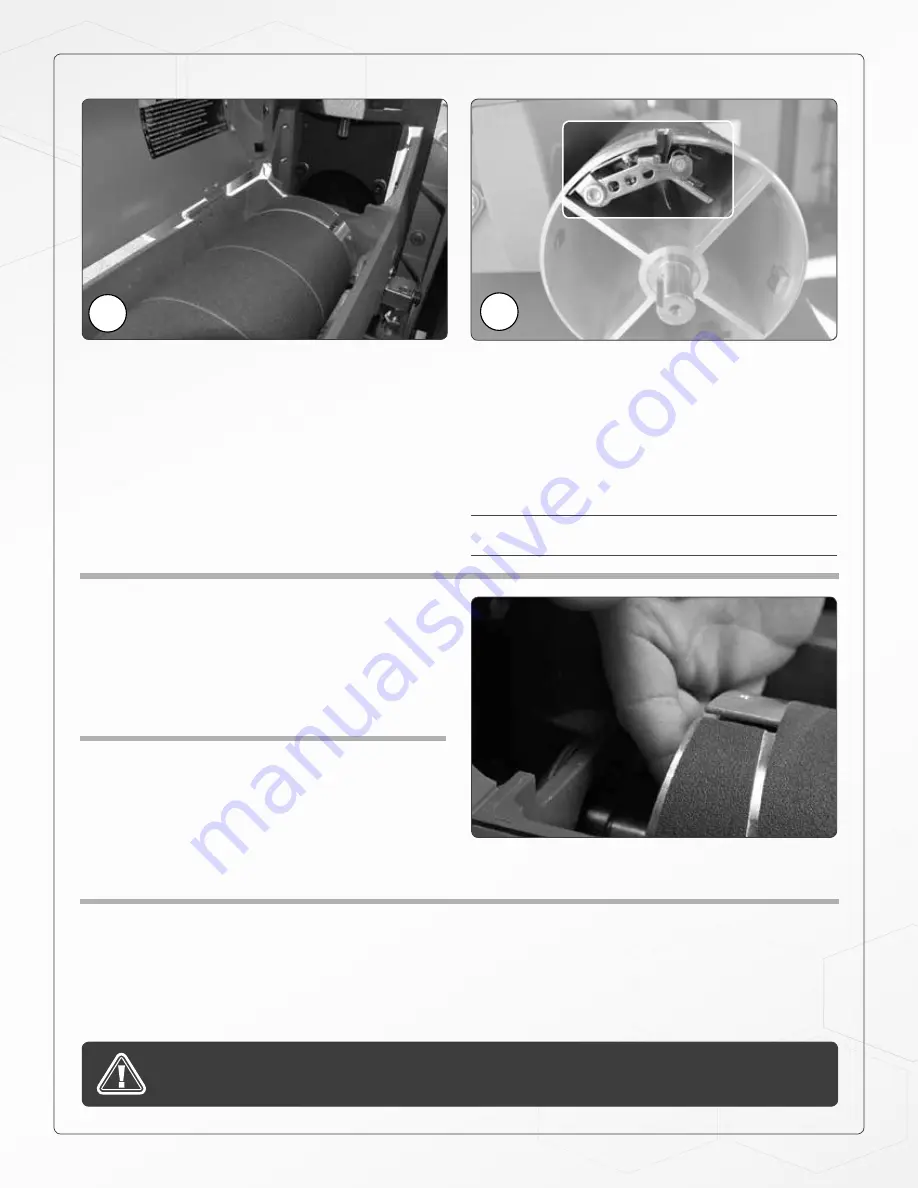

Pinch or squeeze the clip lever to open the clip, and

pull the take-up lever to the top. Insert the tapered end

through the slot in the inboard (right) end of the drum.

The take-up fastener is designed to automatically take

up any slack caused by stretching of the abrasive

wrap. The abrasive wrap may stretch enough in use

to allow the take-up lever to reach its lowest position

so it no longer is able to maintain tension on the wrap.

If this occurs, it will be necessary to reset the take-up

lever by raising it, pushing the wrap end into the slot,

and then releasing the clip lever.

NOTE: Take notice that for detail only the drum was removed

to show the inboard (right) take-up fastener.

PROPER ABRASIVE WRAP POSITION

Position the abrasive wrap in the slot with sufficient

room between the inside of the slot and the tapered

end of the wrap to allow it to be pulled into the drum

as needed (see opposite picture). If enough space is

not left between the wrap and the inside of the slot the

take-up fastener will not operate properly.

ABRASIVE WRAP TENSION ADJUSTMENT

The abrasive wrap may stretch enough in use to allow

the take-up lever to reach its lowest position. If this oc

-

curs then tension is not longer maintained on the abra-

sive wrap. To fix this reset the take-up lever by raising

it, pushing the abrasive wrap into the slot and then re-

leasing the clip lever.

MAXIMIZING ABRASIVE LONGEVITY

A sandpaper cleaning stick may be used to remove deposits and help extend the life of the abrasive.

1.

To use the cleaning stick, operate the sanding drum with the dust cover open and dust collection on.

2.

Hold the cleaning stick against the rotating drum and move it along the drum surface.

3.

Use a shop brush to remove any cleaning stick remnants from the drums before resuming sanding operations.

FOR YOUR OWN SAFETY ALWAYS WEAR EYE PROTECTION WHILE PERFORMING ABRASIVE CLEANING

AND TAKE ALL PRECAUTIONS TO AVOID ANY CONTACT WITH HANDS OR CLOTHING ON THE UNCOVERED.

3

4