18

hardwoods, using a shallower depth of cut and a

faster feed rate will help minimize burn marks.

Slightly angling the stock as it is fed into the

machine may also help prevent burning the stock.

Because of the wide range of variables, it is

important to experiment with your specific

conditions and make adjustments to achieve the

optimum feed rate. If problems occur, check the

depth of cut and/or adjust the feed rate.

Figure 32

Edge sanding

The extension table (Figure 33) is installed for

edge sanding. It can be slid in close to the dust

cover for edge sanding or slid out for opening the

dust cover.

Position the extension table level with or slightly

below the dust cover surface for proper support of

stock. To check position, place a straight edge on

top of the dust cover and extending out over the

extension table.

The plate (A, Figure 34) can be removed to allow

edge sanding and remounted as a vertical guide

fence. Raise rear drum until it just contacts with

the workpiece but still can be rotated by hand.

Feeding direction is from the rear of machine

to the front as the red arrows shown in Figure

34.

Figure 33

Figure 34

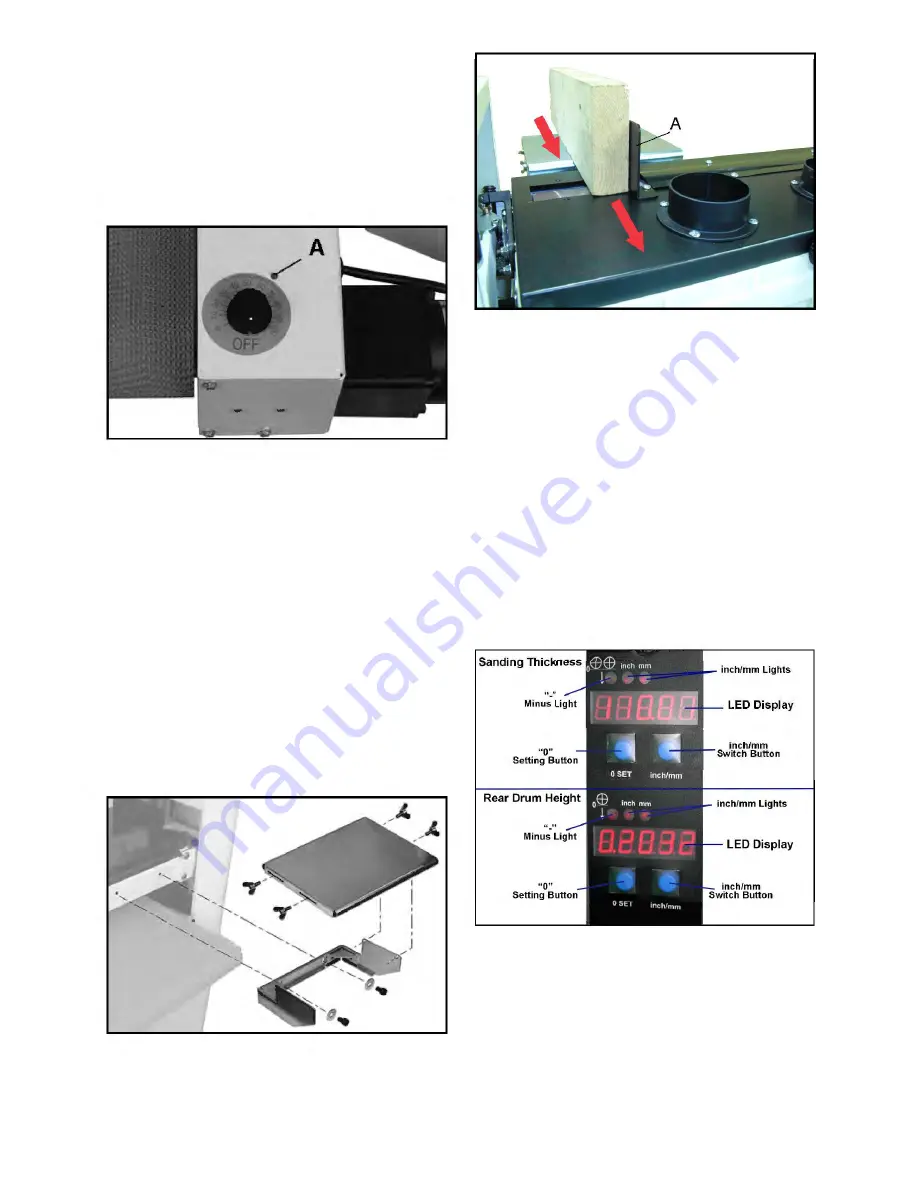

Digital Readout

Figure 35 identifies parts of the digital readouts.

0 SET

– zero-setting

Press this button to set current position as zero

point.

inch/mm

– inch/millimeter

Pressing this button back and forth between

imperial and metric, and can be done at any time

without affecting saved settings.

The DRO comes with memory function. The LED

display will display with "-----" flash when it is

saving the setting. The setting will be kept in the

device’s memory, but it needs re-setting if you

move the drums after power off.

Figure 35

Digital readout for rear drum height

It displays the distance of the rear drum vertical

motion. It is helpful for selecting grits to use on

this dual drum machine and setting the rear drum.

There is an easy method of establishing the rear

drum to zero for this function, as follows.

1. Disconnect sander from power source.

Summary of Contents for 913003

Page 25: ...25 Exploded View Machine Body Assembly...

Page 29: ...29 Exploded View Drum Head Assembly...

Page 32: ...32 Exploded View Conveyor and Motor Assembly 33 1Ph...

Page 39: ...39 Notes...