23

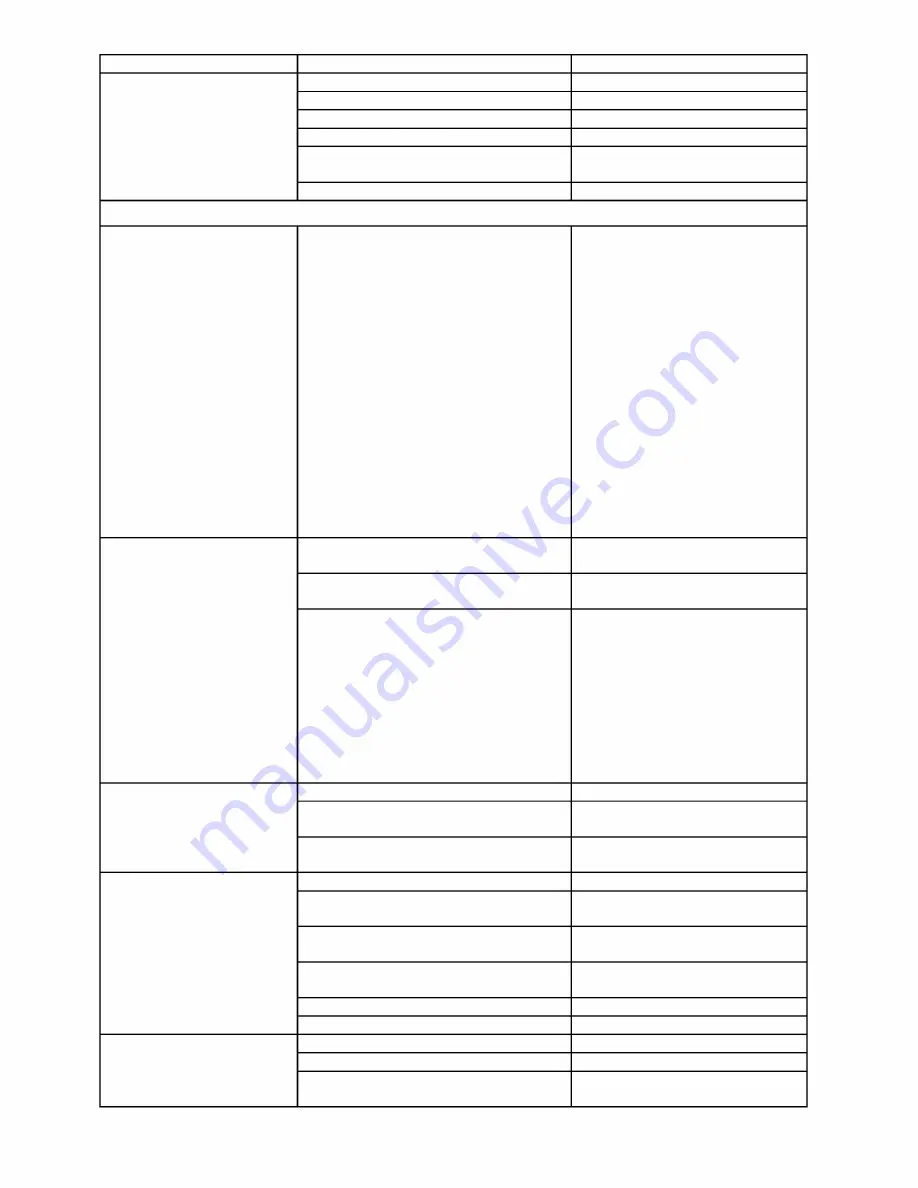

Drum drive belt slips.

1. Improper poly-v belt tension.

Increase belt tension.

1. Poly-v belt worn.

Replace poly-v belt.

2. Loose weight in drum.

Glue weight back in place.

3. Pulleys wobbling or out of round.

Replace pulley.

4. Set screws loose in pulleys.

Retighten or replace set screws.

5. Abrasive fastener on drum loose

(without abrasive strip in place).

Insert abrasive paper, or replace

fastener.

Knocking sound while

running.

6. Drum or motor bearing worn.

Replace bearing.

Troubleshooting guide: Operations

Rippled sanded surface

(non-uniform ripples).

1. Uneven feed rate.

Check for these conditions and

refer to previous section,

Troubleshooting: Machine.

1.

See section Selecting feed

rates.

2.

Conveyor belt slipping on

drive roller.

3.

Board slipping on conveyor

belt.

4.

Conveyor gear motor

stalling.

5.

Improper poly-v belt

tension.

6.

Set screw loose on shaft

coupler between gear

motor and conveyor.

7.

Conveyor bushings dry;

lubricate.

1. Excessive feed rate.

Reduce depth of cut or reduce

feed rate.

2. Excessive depth of cut.

Reduce depth of cut or reduce

feed rate.

Rippled sanded surface

(uniformly spaced ripples).

3. Sander vibration.

Check for these conditions:

1.

Loose bolts or bearing and

pulley set screws;

retighten.

2.

Dirty drum; clean inside.

3.

Excessive belt tension;

reduce tension.

4.

Worn poly-v belt; replace.

5.

Warped driven pulley;

replace.

1. Tension rollers set too far down.

Reset tension rollers.

2. Stock not supported properly during

infeed or outfeed.

Support stock with roller stands,

tables or benches.

Sniping of wood (gouging

near end of board).

3. Conveyor drive or driven rollers

higher than conveyor bed.

Readjust rollers.

1. Feed rate too slow.

Increase feed rate.

2. Excessive depth of cut for grit used.

Reduce depth of cut or increase

grit coarseness.

3. Excess build-up on abrasive strips.

Reduce depth of cut; clean strips

or replace.

4. Abrasive is too fine.

Replace with abrasive of coarser

grit.

5. Abrasive strips overlapped.

Rewrap strip without overlap.

Burning of wood.

6. Drum out of alignment.

Realign drum.

1. Conveyor belt is too loose.

Adjust belt tension.

2. Excessive depth of cut.

Reduce depth of cut.

Gouging of wood.

3. Wood slipping on conveyor due to

lack of contact.

Use alternate feeding procedure.

Summary of Contents for 913003

Page 25: ...25 Exploded View Machine Body Assembly...

Page 29: ...29 Exploded View Drum Head Assembly...

Page 32: ...32 Exploded View Conveyor and Motor Assembly 33 1Ph...

Page 39: ...39 Notes...