RUNNING IN, MAINTENANCE AND REPAIRS

RUNNING-IN PROCEDURE

IMPORTANT

Ensure your winch wormbox has been filled with oil prior to use.

MAINTENANCE AND REPAIRS

Periodically check tightness of mounting bolts and electrical connections. Remove any dirt or corrosion that may

have accumulated on the electrical connections.

Repair should be carried out by Authorised Superwinch Repair Centres only. Do not attempt disassembly of the

gearbox. Disassembly will void warranty.

After the first 1 hour of operation:

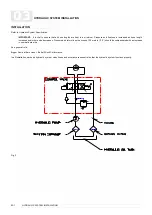

Change the Gearbox oil (See Fig. 8 for location of drain hole and level plug).

Check tightness of mounting bolts and electrical connections.

Monthly:

Check oil level in worm gear box. Oil level should be maintained to the lower edge of the level plug hole

with the winch in the upright position as shown in Fig. 8.

After 10 hours of winching or annually:

Change Worm Gearbox oil. Check tightness of mounting bolts and

electrical connections.

Wormbox Gearbox

: The winch is delivered from the factory filled with the correct type and quantity of oil.

Change the oil in the gearbox at least once a year. The oil specification recommended is BP MULTIGEAR FE

85/140 or equivalent, using approximately 3/4 litre (0.2 U.S. gal).

LUBRICATION

The spur and worm gearboxes are self contained and individually lubricated. The spur gearbox is factory filled for

life with BP Energrease FGL which is suitable for most climates. In extreme climates, (below 13°C or above 43°C)

contact Superwinch for advice.

CLIMATE

TEMPERATURE

GEARBOX OIL

Arctic

-13°C to 15°C

SAE 90 Oil

(8°F to 59°F)

Temperate

-16°C to 29°C

SAE 85/140 Oil

(3°F to 85°F)

Tropical

19°C to 43°C

SAE 140 Oil

66°F to 100°F)

NOTE :

EP (Extreme Pressure) additives can damage copper based alloys like phosphor bronze used for the

worm gear and we do not recommend their use in the worm gearbox. If any doubt exists, consult your lubricant

supplier’s technical department.

The drum bearings and splined drum clutch are lubricated with molydisulphide loaded bearing grease.

08

RUNNING IN, MAINTENANCE AND REPAIRS

08-1

Fig. 8