6. EQUIPPING THE WINCH WITH A

ROLLER FAIRLEAD will substantially

reduce wear on the wire rope

during angle pulls (Figure 11).

The rollers eliminate heavy rubbing

and abrasion to the wire rope.

Periodically check tightness of

mounting bolts and electrical con-

nections. Remove any dirt or corro-

sion that may have accumulated on

the electrical connections.

Repairs should be done by

Authorized Superwinch Repair

Centers ONLY. Do not attempt to

disassemble the gearbox.

Disassembly will void warranty.

LUBRICATION

The gearbox and drum bearing are

permanently lubricated with a high

performance gear lube.

REPLACING THE WIRE ROPE

Never substitute a heavier or lighter

wire rope. Never use rope made of

any other material other than wire.

Always use wire rope with a mini-

mum breaking strength of 10,800

lbs. (48kN).

Always replace damaged wire

rope with manufacturer’s

identical replacement part

(see

Replacement Parts list). Pass attaching

end of wire rope through the fairlead (if

equipped) and attach it to the drum.

When inserting the wire rope into

the drum, insert it into the correct

end of the hole provided (Figure

12). Tighten the set screw securely.

It is important that the wire rope

be wound tightly onto the drum.

A good way to do this is to attach

the wire rope hook to a fixed object

at the top of a slight incline, then

winch the vehicle up the incline.

When wire rope is removed from

the drum, as in bringing the hook

to the load, the freewheel feature

of the winch should be used.

BRAKE OPERATION

Your winch incorporates a propor-

tional friction-type brake. After

winching in a load, this mechanism

holds the load, up to the rated

capacity of the winch. While power-

ing-out a load, the winch controls

the rate of speed by applying the

brake in proportion to the amount

of the load on the winch cable. This

results in heavier loads powering-

out more slowly than lighter loads.

Similar to the friction-type brakes in

your automobile which can gener-

ate heat if used for a long period of

time, the winch brake can generate-

heat if used to power-out a load for

a long period of time.

To ensure

optimum winch perfromance,

always limit powering-out of a

load to 2 minutes and allow the

brake to cool for 15 minutes

before continuing to winch.

Under normal use, the brake mech-

anism should not require any adjust-

ment. Should the brake fail to hold

a load or maintain a constant rate

of speed during power-out opera-

tion, the brake pad may be worn

and require replacement.

After extended

periods of pow-

ering-out loads against the brake,

the gearbox housing may become

hot.

PULLING OUT THE WIRE ROPE

The wire rope has been installed on your

winch under minimal load at the factory.

The wire rope must be respooled onto the

drum under load so that the outer layers

will not draw down into the inner ones

thereby damaging the wire rope.

1. Rotate the clutch lever to the

“Disengaged” position as shown

in Figure 8. If there is a load on

the wire rope, the clutch lever

may not turn easily. DO NOT

FORCE THE CLUTCH LEVER.

Release tension on the wire

rope by jogging out some of

the wire rope, then try releasing

the clutch.

2. Pull out the wire rope and

secure to anchor or load.

3. Check that there are at least

five (5) turns of wire rope left on

the drum.

4. Re-engage the drum by rotating

the clutch lever to the “Engaged”

position (see Figure 8).

Lever must be in

the engaged posi-

tion and locked before winching.

TIPS FOR EXTENDING THE LIFE OF

THE WINCH

1. KEEP A TIGHTLY WOUND WIRE ROPE

DRUM. Do not allow the wire rope to

become loosely wound. A loosely-

wound drum allows a wire rope under

load to work its way down into the lay-

ers of wire rope on the drum. When this

happens, the wire rope may become

wedged within the body of the wind-

ings damaging the wire rope. To prevent

this problem, keep the wire rope tightly

and evenly wound on the drum at all

times. A good practice is to rewind the

wire rope under tension after each use.

One way to do this is to attach the hook

to a stationary object at the top of a

gradual incline and winch your vehicle

up the incline.

2. DO NOT ALLOW WINCH MOTOR TO

OVERHEAT. Remember, the winch is for

intermittent use only. During long or

heavy pulls the motor will get hot. The

internal parts will be hotter than the

case. To check the motor temperature,

stop winching and carefully touch the

motor case, if the motor is uncomfort-

able to touch, allow the motor to cool

before continuing. KEEP THE ENGINE

RUNNING TO RECHARGE THE BATTERY

during this break.

3. To maximize winch and wire rope life,

use a pulley block to double line heavier

loads (Figure 9).

4. The pull required to start a load moving

is often much greater than the pull

required to keep it moving. AVOID

FREQUENT STOPPING AND STARTING

during pull.

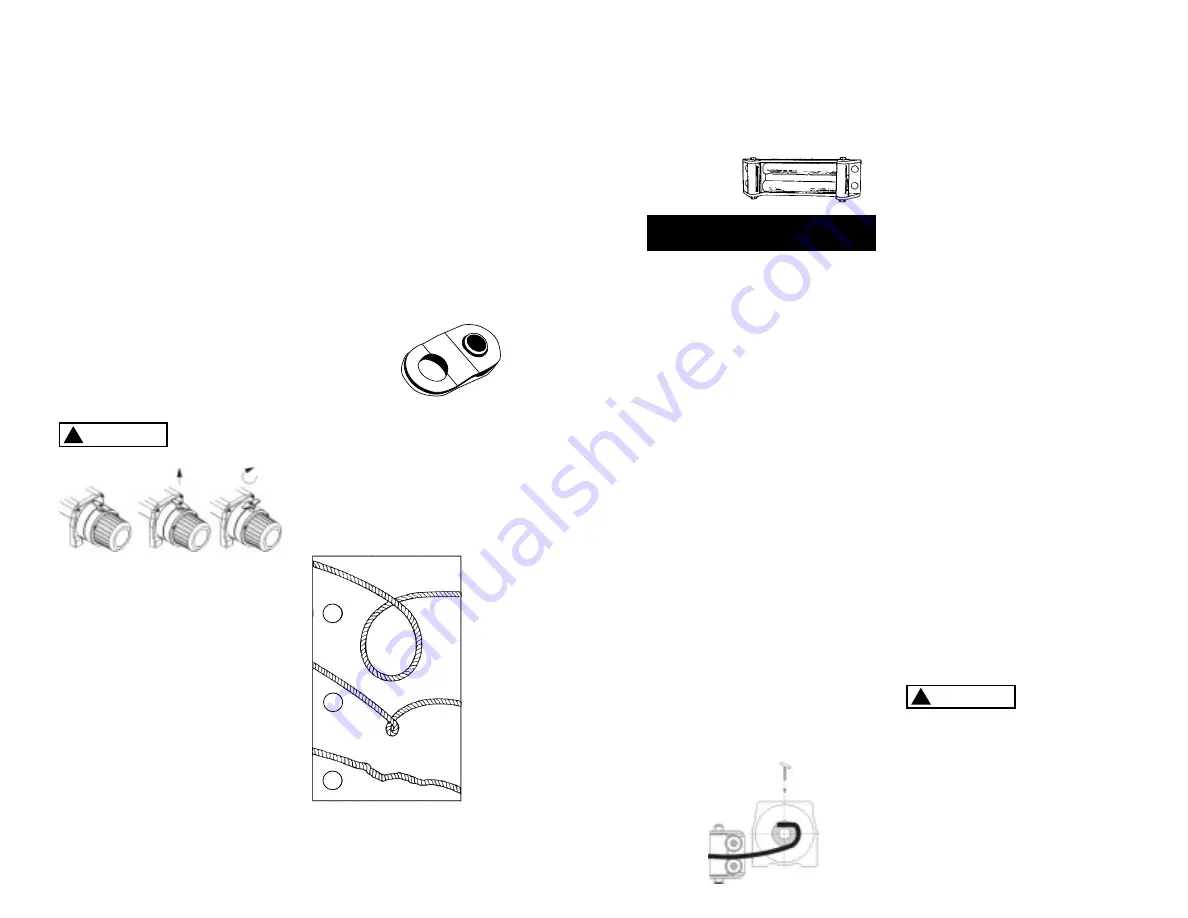

5. PREVENT KINKS BEFORE THEY OCCUR.

(FIGURE 10).

CAUTION

!

10

11

Figure 10

a

b

c

a

. This is the start

of a kink. Wire

rope should be

straightened.

b

. Wire rope was

pulled and loop

has tightened into

a kink.

Wire rope

is now perma-

nently damaged

and must be

replaced.

c

. Result of kink-

ing is that each

strand pulls a dif-

ferent amount caus-

ing strands under

greatest tension

to break and

reduce load capac-

ity of wire rope.

The wire rope

must be

replaced.

Figure 11

M A I N T E N A N C E

Figure 12

Figure 8

Figure 9

Engaged

Disengaged

WARNING

!

Summary of Contents for EP/EPi6.0

Page 28: ...54 55 N O T E S N O T E S...