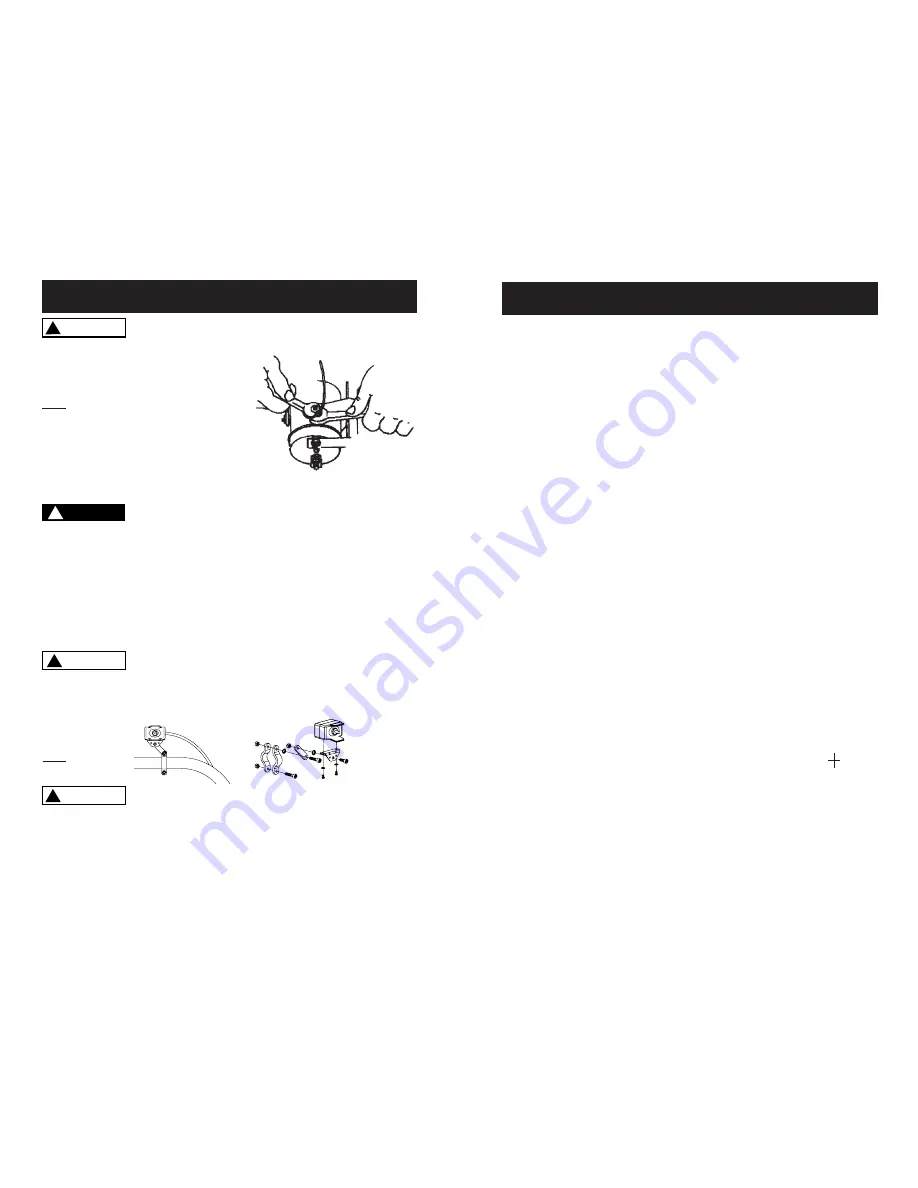

Fig. 4

-

Proper Terminal Tightening

WARNING

!

Ensure that the wiring harness does not interfere or come in con-

tact with any hot or moving engine, suspension, steering, braking

or exhaust parts.

TOGGLE SWITCH INSTALLATION

CAUTION

!

When attaching wires to the motor or solenoid terminals, hold the

inner nut with a wrench while tightening the outer nut with a

second wrench. Do not allow the terminals to rotate in their housings. Rotation may cause

internal wire breakage or part misalignment ( Fig 4).

Step ( 1 )

Check to ensure that the vehicle ground and positive leads from the battery are

disconnected before performing any electrical work.

DANGER

!

DO NOT ATTEMPT TO INSTALL WIRING WHEN THE BATTERY IS

CONNECTED. Automotive batteries contain flammable and

explosive gases. Wear eye protection during installation and remove all metal

jewelry. Do not lean over battery while making connections.

Step ( 2 )

Route the wiring harness, attaching the harness to hard points on the vehicle with

cable ties.

Step ( 3 )

Using the supplied clamps, bracket and hardware, mount switch in a convenient

location. See

Fig. 5.

Fig. 5

Step ( 4 )

It is recommended that the switch be installed on the left handlebar.

Step ( 5 )

Once the switch is mounted, route the jacketed

green and black

leads back to where

the solenoid is mounted. Splice the red lead into wire that energizes with ignition

switch on and de-energizes with ignition off.

WIRING INSTALLATION

On the top of the

solenoid

, connect the RED 6 ga. wire to the terminal

C

.

Route the opposite end of the RED 6 ga. wire to

the

circuit breaker

and connect the RED

6 ga. wire to the unmarked side of the

circuit breaker

. (see Fig. 6)

Step ( 3 )

On the top of the

solenoid

, connect the BLACK 6 ga. wire to terminal

D

. (see Fig. 3)

On the

solenoid

, check that the short BLACK jumper wire lead, is installed from the

solenoid’s

center

flat spade connector

E

, to the

solenoid’s

terminal

D

. (see Fig. 3).

Attach the BLACK wire from the

rocker switch

to the outer

left

spade,

F

connector, of

the

solenoid.

Attach the BLACK wire from the

optional

socket assembly

to the same

outer

left

spade connector,

F

.

note; the solenoid top side up

(see Fig. 6 and 3)

Attach the GREEN wire from the

rocker switch

to the outer

right

spade connector

G

on the

solenoid

. Attach the GREEN wire from the

optiona

l

socket assembly

to the

same outer

right

spade connector

G

.

note; the solenoid top side up

(see Fig. 6 and 3)

Step ( 7 )

Connect the RED WIRE, from the

rocker switch

and

optionaly

from the

socket

assem-

bly

to your ATV’s Ignition Switch key controlled wire. This wire must only have power

when the key is in the on position. A fuse protected key controlled wire is prefered.

Fuse should be rated for at least 4 amps. Cover-wind the connection with muti-layers

of CE approved electrical insulation tape, (see Fig. 6).

Note:

When routing the wires, the appropriate terminals should be located near the

battery, switch mounting point, and winch. Your installation requirements will vary

depending upon your vehicle and winch. Make sure wires are long enough to reach

the battery, switch mounting point and winch.

CAUTION

!

ALWAYS USE THE SWITCH MOUNTING BRACKET, SCREWS, AND

LOCK NUTS PROVIDED. Screw lengths are sized for correct

penetration into switch box. Excess penetration may result in short circuits that could

lead to wire over heating.

Route the opposite end of the BLACK wire from,

solenoid

terminal

D,

and connect

to

the “-” negative terminal on the

battery

. (see Fig. 6)

Connect the short RED 6 ga. wire to the end of the

circuit breaker

, marked “ “positive.

Connect the other end of this RED wire to the “+” positive

battery

terminal. (see Fig. 6)

Step ( 9 )

Step ( 8 )

Step ( 10 )

Check that all wiring is clear of sharp edges and pinch points. Check that all wiring is

firmly connected to it’s proper terminal or spade connector. Secure loose wiring with

tie wraps and electrical insulation tape.

7

Step ( 1 )

Connect the YELLOW 6 ga. wire to the #

1

“

+

” positive terminal on the

motor

and connect

the BLUE 6 ga. wire to #

2

“

-

” negative terminal to the

motor

. (see Fig. 6)

Route the opposite ends of the YELLOW 6 ga. and the BLUE 6 ga. wires back to the solenoid.

On the top of the

solenoid,

connect the YELLOW 6 ga. wire to terminal

A

“+” positive.

Also, on top of the

solenoid

connect the BLUE 6 ga. wire to terminal

B

“-” negative. (see Fig. 3)

6

Step ( 2 )

Step ( 4 )

Step ( 5 )

Step ( 6 )