9

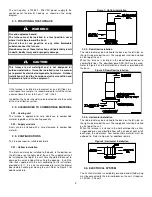

Figure 14 : Advantage furnace controls

3.3- OPERATING SEQUENCE

This unit is designed to provide the required airflow in order to

match with any of four (4) different electronic heat capacity, air

conditioner or heat pump outdoor unit sizes (see Tables 3 and 4

for CFM values).

Also, the blower motor is a true variable speed motor designed

to deliver constant CFM. Constant CFM is valid for systems with

total external static pressure between 0.1 and 0.8 inches water

column.

Refer also to Table 1 for sequence of operation summary,

depending on thermostat inputs and types.

3.3.1- Continuous fan

•

Thermostat closes circuit R to G.

•

Blower runs at continuous fan airflow.

3.3.2- Cooling mode – single stage

•

If indoor temperature is above temperature set point and

humidity is below humidity set point, thermostat closes

circuits R to G, R to Y/Y2 and R to O.

NOTE:

For single stage systems, do not use the Y1 terminal.

•

Furnace delivers single stage cooling airflow.

3.3.3- Cooling mode – two stage

•

First stage (low) cooling: Thermostat closes circuits R to G,

R to O, and R to Y1.

•

Furnace delivers low stage cooling airflow.

•

Second stage (high) cooling: Thermostat closes circuits R

to G, R to O, R to Y1 and R to Y/Y2.

•

Furnace delivers high stage cooling airflow.

3.3.4- Cooling mode – dehumidification

NOTE:

Remove jumper « J1 » on board to activate this function.

(Refer to Figure 10 and Figure 16)

•

If indoor temperature is above temperature set point and

humidity is above humidity set point, thermostat closes

circuits R to G, R to Y/Y2 and R to O and humidistat opens

circuit R to DH.

•

The furnace delivers airflow which is approximately 80% of

the nominal cooling airflow to increase the latent capacity of

the system.

3.3.5- Electric heating mode – 1 stage

•

Thermostat closes circuit R to W1 or W2.

•

Furnace delivers the selected electric heat airflow and

maximum heating capacity is powered starting the heating

elements in sequence with a delay of 8 seconds between

each.

3.3.6- Electric heating mode – 2 stage

NOTE:

Remove jumper « J2 » on board to activate this function.

(Refer to Figures 9 and 15)

•

First stage heating: thermostat closes circuit R to W1.

•

Furnace delivers low stage heating airflow (50% of nominal

electric heating airflow) and approximately half of the

heating capacity is powered starting the heating elements

in sequence with a delay of 8 seconds between each.

•

Second stage heating:thermostat closes circuit R to W2.

•

Furnace delivers high stage heating airflow (100% of

nominal electric heating airflow) and maximum heating

capacity is powered starting the heating elements in

sequence with a delay of 8 seconds between each.

3.3.7- Heat pump heating mode – single stage

•

Thermostat closes circuits R to G and R to Y/Y2.

NOTE:

For single stage systems, do not use the Y1 terminal.

•

Furnace delivers single stage heat pump heating airflow.

3.3.8- Heat pump heating mode – two stage

•

First stage (low) heating: Thermostat closes circuits R to G

and R to Y1.

•

Furnace delivers low stage heating airflow.

•

Second stage (high) heating: Thermostat closes R to G, R

to Y1 and R to Y/Y2.

•

Furnace delivers high stage heating airflow.

WARNING

Electrical shock or unit damage hazard

Failure to carefully read and follow this WARNING could

result in equipment malfunction, property damage,

personal injury and/or death.

Disconnect power to unit before removing or replacing

connectors or servicing motor. Wait at least five (5) minutes

after disconnecting power before handling.

3.4- AIRFLOW VERIFICATION

Verify the airflow by taking readings of the following points, while

the elements are in heating mode:

a. Total amperage of all the heating elements;

b. Voltage at the furnace;