Gas Requirements

L.P. GAS INSTALLATION

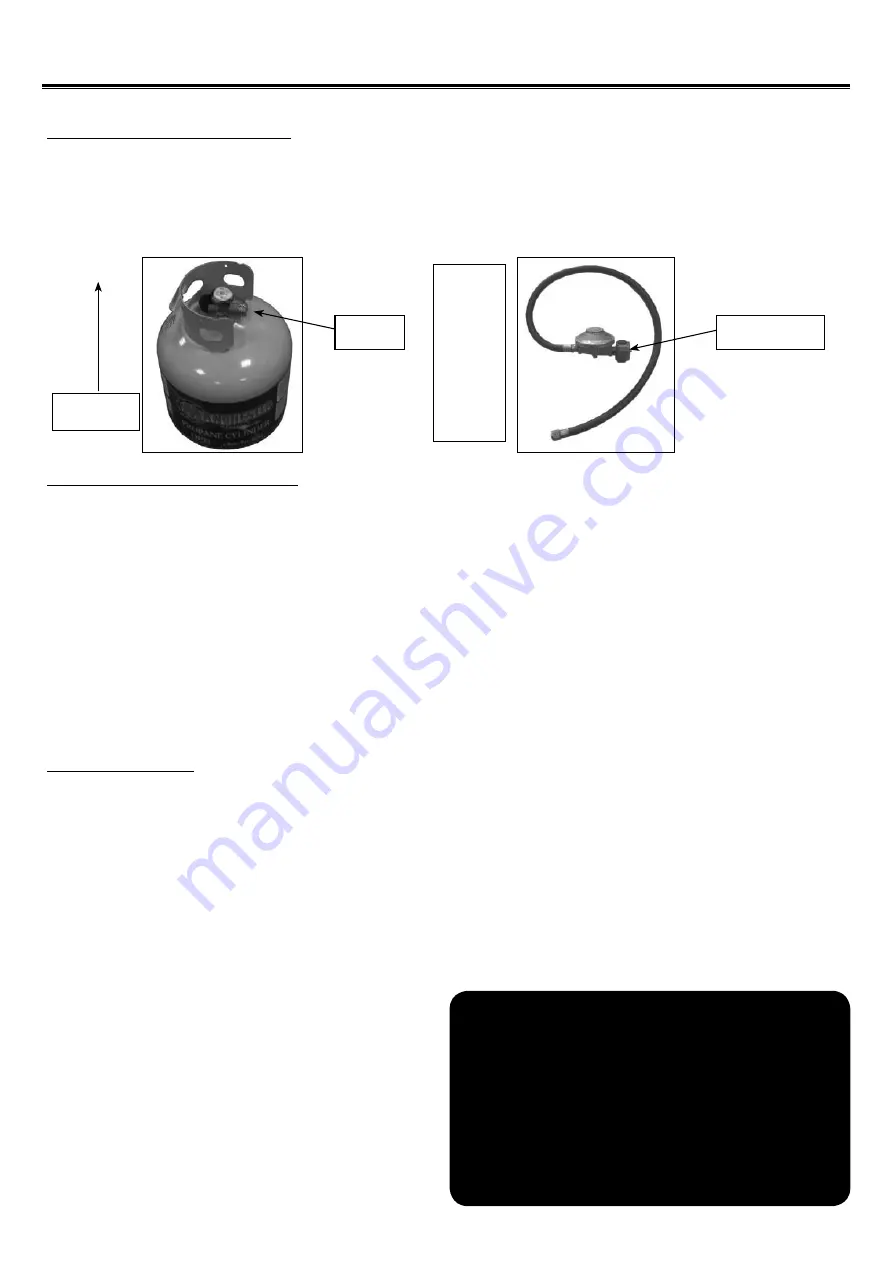

Gas Heaters that are set to operate with L.P. gas come with a high capacity hose and regulator assembly.

(Note: Only use the pressure regulator and hose assembly supplied with the heater or a replacement

pressure regulator and hose assemblies ).

This assembly is designed to connect directly to a standard

20 lb. L.P. cylinder. L.P. Cylinders are not included with the heater. L.P. Cylinders they can be purchased

separately at an independent dealer.

L.P. TANK INFORMATION

Never use a dented or rusted L.P. tank or cylinder with a damaged valve.

L.P. cylinders are equipped with an O.P.D (Over

fi

lling Prevention Device). The device shuts off the

fl

ow of gas

to a cylinder after 80% capacity is reached. This limits the potential for release of gas when the cylinder is

heated, averting a

fi

re or possible injury.

The L.P. cylinder must have a shut-off valve terminating in an L.P. gas supply cylinder outlet specified,

as applicable, for connection No. 510 in the standard for compressed gas cylinder valve outlet and inlet

connection ANSI/CGA-V-1. Cylinders must not be stored in a building, garage, or any other enclosed area. (The

L.P. cylinder must have an over

fi

ll protection device, OPD, and a collar to protect the cylinder valve.)

The L.P. gas supply cylinder must be constructed and marked in accordance with the speci

fi

cations for L.P.

gas cylinders of the U.S. Department of Transportation (DOT) or the National Standard of Canada, CAN/

CAS-B339, “ Cylinders, Spheres and Tubes for the Transportation of Dangerous Goods and Commission.”

L.P. TANK USE

• When turning the L.P. tank on, make sure to open the valve SLOWLY two (2) complete turns to

ensure proper gas flow. Most gas tanks now come equipped with a leak detector mechanism

internal to the tank, when gas is allowed to escape rapidly it shuts off the gas supply. Opening the

valve rapidly may simulate a gas leak, causing the safety device to activate, restricting gas flow

causing low

fl

ames. Opening the valve slowly will ensure this safety feature is not falsely triggered.

• When not in use, gas supply cylinder valve is to be in the “ OFF” position.

• The tank supply system must be stored upright to allow for vapor withdrawal.

• The regulator and hose assembly must be inspected before each use of the heater. If there is excessive

abrasion or wear or if the hose is cut, it must be replaced prior to the heater being used again.

• Cylinders must be stored outdoors out of the reach of

children and must not be stored in a building, garage

or any other enclosed area.

• Only a qualified gas supplier should refill the L.P.

tank.

• Place dust cap on cylinder valve outlet when ever

the cylinder is not in use. Only install the type of dust

cap on the cylinder valve outlet that is provided with

the cylinder valve. Other types of caps or plugs may

result in leakage of propane.

16

Upright Tank

Orientation

Tank

connection

LP hose/

regulator

supplied

(Type 1

connector)

Regulator Inlet

Connectot

▲

!

WARNING

DO NOT store a spare L.P. gas cylinder under or near

the heater. Never fi ll the cylinder beyond 80% full.

If this information is not followed exactly, a

fi re causing death or serious injury may occur.