WWW.PEAKWORKS.CA

5

6

8

6a

7

11

9

6

3. The recovery mechanism has only been approved for recovery purposes, not for lifting and

lowering loads.

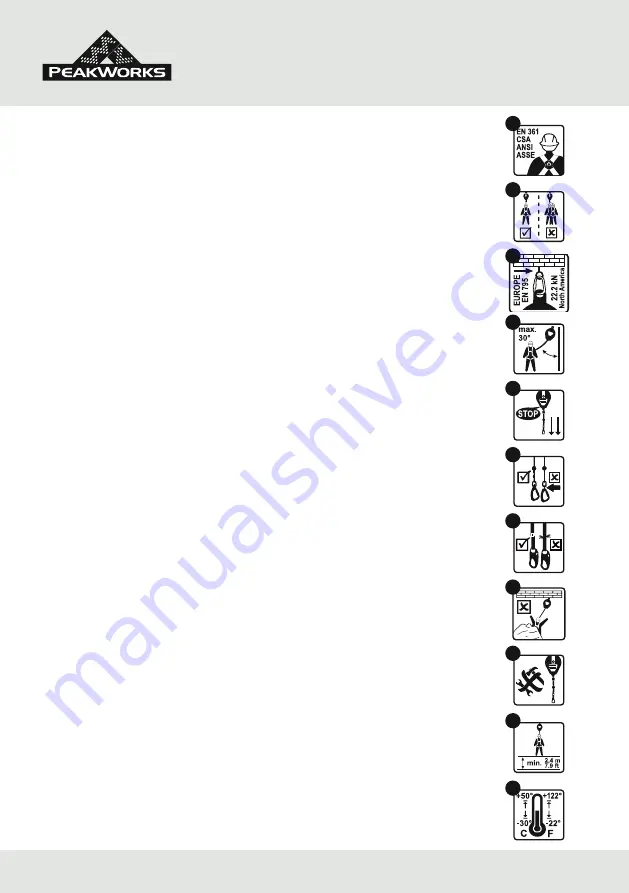

4. Only safety harnesses in accordance with EN 361, EN 361/1497, CSAZ259.2.2 type A or D, ANSI/

ASSE Z359.1-2007 are permitted for use with the fall arrest block with recovery mechanism (other

harnesses are not permitted) (Fig. 2).

5. One device can only protect one person at a time, but can be used successively by several

persons (Fig. 3).

6. A rescue plan covering any rescue case that might occur during work must exist.

7. During the rescue operation, there must always be direct or indirect visual or communicative

contact with the person to be rescued.

8. For devices with a hand chain drive, a suitable attachment point of sufficient carrying capacity

must be chosen (e.g. anchorage point in accordance with EN 795; or 7.5 kN carrying capacity

(for North America 22,2 kN) at present constructions; BGR 198) (Fig. 4). Attachment is made

using a suitable connecting element in accordance with EN 362 or sling rope, the rope being

pulled through the handle of the fall arrest block and closed with a secured connecting element in

accordance with EN 362:2004 / CSA Z259.12-01 /ANSI /ASSE Z359.12-2009.

9. This device should be in a perpendicular position above the head of the person to be rescued

in order to prevent swinging (Fig. 5). The suspension of the device must allow for compensating

deviations in cable/webbing length. When the device has been attached to the anchorage point,

attach the end of the connecting device (carabiner type connector) to the ring attachment point of

the safety harness. If the carabiner hooks are not self-locking, they must be screwed tight with a

sleeve nut.

10. This recovery block with winding handle can only be used as part of a fall arrest system

in conjunction with the holders and support brackets of the PeakWorks anchor devices in

accordance with EN 795. The instructions for use of the anchor devices and their components

must be observed.

11. Before every use, check the readability of the product label.

12. A visual inspection and functional test of this SRL must be performed before every use (Fig. 6). To

do so, attach the fall arrest block to a suitable anchor point: Pull the cable, the ratchets must lock

audibly and the device must be locking. Firmly hold the cable and allow it to retract into the fall

arrest block in a controlled manner. If the cable is released, it may cause injuries and damage by

its quick and uncontrolled retraction into the housing. Check the swivel hook for proper functioning

(self-closing, lockable). Check the retractable connecting device for proper condition. A recovery

block with a damaged connecting element or device (Fig. 6a and 7), e.g. cable with a kink or

broken/torn strand, must not be used.

13. A fall arrest block must be withdrawn from use if damaged, loaded by fall or if its safe condition is

doubtful. It may only be used further if tested and released in writing by an expert from or trained

by the manufacturer. * Check connector to ensure that the indicator has not been released.

14. Fall arrest blocks must not be used for securing persons working above bulk goods or similar

substances where people can sink in (Fig. 8).

15. As necessary, but at least every 12 months, fall arrest blocks with recovery mechanism must be

inspected by the manufacturer or by persons trained and authorized by the manufacturer (Fig. 9).

This must be documented in the inspection log book supplied with the product. The effectiveness

and durability of the fall arrest block depends on regular inspection.

16. Observe BGR198 (fall) and BGR199 (rescue operation).

17. With the fall arrest block above the user, the clear height below the user must be 2.4 m (Fig. 10).

18. The PeakWorks SRL with recovery mechanism can be used in a temperature range from

-30° C to +50° C (Fig. 11).

19. The rated load is 300 lbs (136 kg) (Fig. 12).

2

4

3

10

Summary of Contents for PeakWorks SRL-53303-138

Page 2: ...Pr fbuch_Peakworks_HRA_GB FR_07112016...

Page 23: ......